Where we provide instant quotes

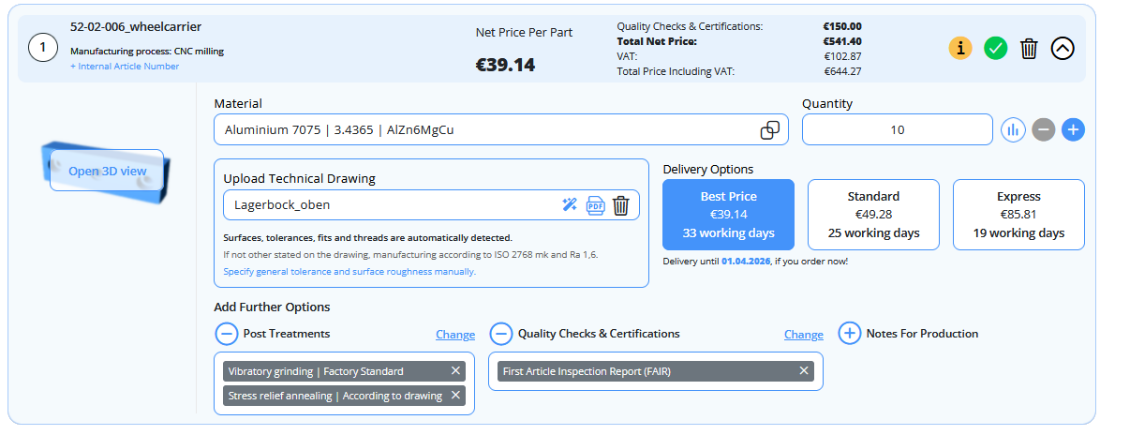

Instant quoting works best when requirements are captured clearly and consistently. For CNC milling, CNC turning, and downstream steps like post-processing and quality control, we generate quotes from your CAD data and configuration inputs, and use drawings where specifications must be interpreted precisely. This keeps pricing fast while ensuring lead time, feasibility, and inspection expectations are aligned from the start.

What can be quoted

Prismatic and freeform parts produced via 3-axis to multi-axis CNC milling – including pockets, slots, contours, drilled and tapped holes, counterbores/countersinks, and milled faces for tight fits. Suitable for prototypes through small and medium batch sizes, across common metals and engineering plastics.

What the quote is based on

Primary driver is the 3D CAD geometry (feature complexity, tool access, setups, machining time), combined with your configuration inputs like material, quantity, tolerance class, surface finish requirements, threads, and any special notes. A 2D drawing (PDF) is used when critical dimensions, GD&T, fits, or inspection notes must be interpreted beyond what the CAD alone conveys.

CNC Turning

What can be quoted

Rotational parts made on CNC lathes – shafts, sleeves, bushings, spacers, threaded parts, grooves, undercuts, bores, and facing operations. If required, turning quotes can also include typical secondary operations (for example cross-holes or simple milled flats) when defined in the geometry and requirements.

What the quote is based on

The pricing logic is anchored in the turned geometry (diameters, lengths, internal features, cut-off strategy, and number of operations) plus your inputs for material and quantity. A drawing (PDF) becomes especially relevant for thread specifications, fits, runout/concentricity requirements, surface finish callouts, and any notes that affect setup, gauging, and cycle time.

Post-Processing and Quality Control

What can be quoted

Post-processing options that finalize function and appearance – for example deburring, bead blasting, anodizing, or marking. Quality control can be quoted as different inspection levels, from standard dimensional checks up to defined measurement documentation, including material or coating certificates when requested.

What the quote is based on

Post-processing is driven by the selected finish specification and how the part’s material and geometry influence preparation effort, masking needs, surface exposure, and handling complexity. Quality control pricing is based on what must be verified and documented: drawing requirements (especially GD&T, fits, and critical characteristics), the requested inspection depth, batch size, and the amount of reporting needed – typically requiring the PDF drawing to avoid ambiguity and align inspection to the exact specification.

Ordering CNC Machined Parts Online

has never been easier

Quotes in a matter of seconds and the power that comes from thousands of CNC production machines: With InstaWerk, we make the procurement of CNC milled parts cost-efficient, fast and highly scalable.

Instant Quotes for CNC machined parts based on CAD-files and drawings

Our intelligent algorithms instantly analyze the CAD models and the technical drawings of your CNC components and calculate a price immediately.

Convenient.

Orders for milled parts or turned parts can be completed in just a few clicks using our cloud-based calculation software.

Cost-efficient.

By bundling orders and long-term framework agreements, we create unbeatable conditions for our customers.

High-Quality.

Top level milled parts through continuous quality monitoring, data analysis and rigorous processes.

Scalable.

From prototype to large-scale production: We offer unlimited resources and maximum availability.

Why Instant Quoting Changes Sourcing

From first CAD upload to decision-ready pricing in minutes – without sacrificing engineering rigor.

Instant quoting for CNC machining – milling and turning – gives procurement and engineers decision-ready pricing in minutes, with clear lead times and transparent assumptions. It accelerates RFQs, improves quote comparability across suppliers, and cuts coordination overhead. Engineers get earlier manufacturability feedback and faster design-to-cost iteration directly from CAD. The result is faster sourcing cycles, fewer revisions, and reliable CNC part pricing for prototypes through production batches.

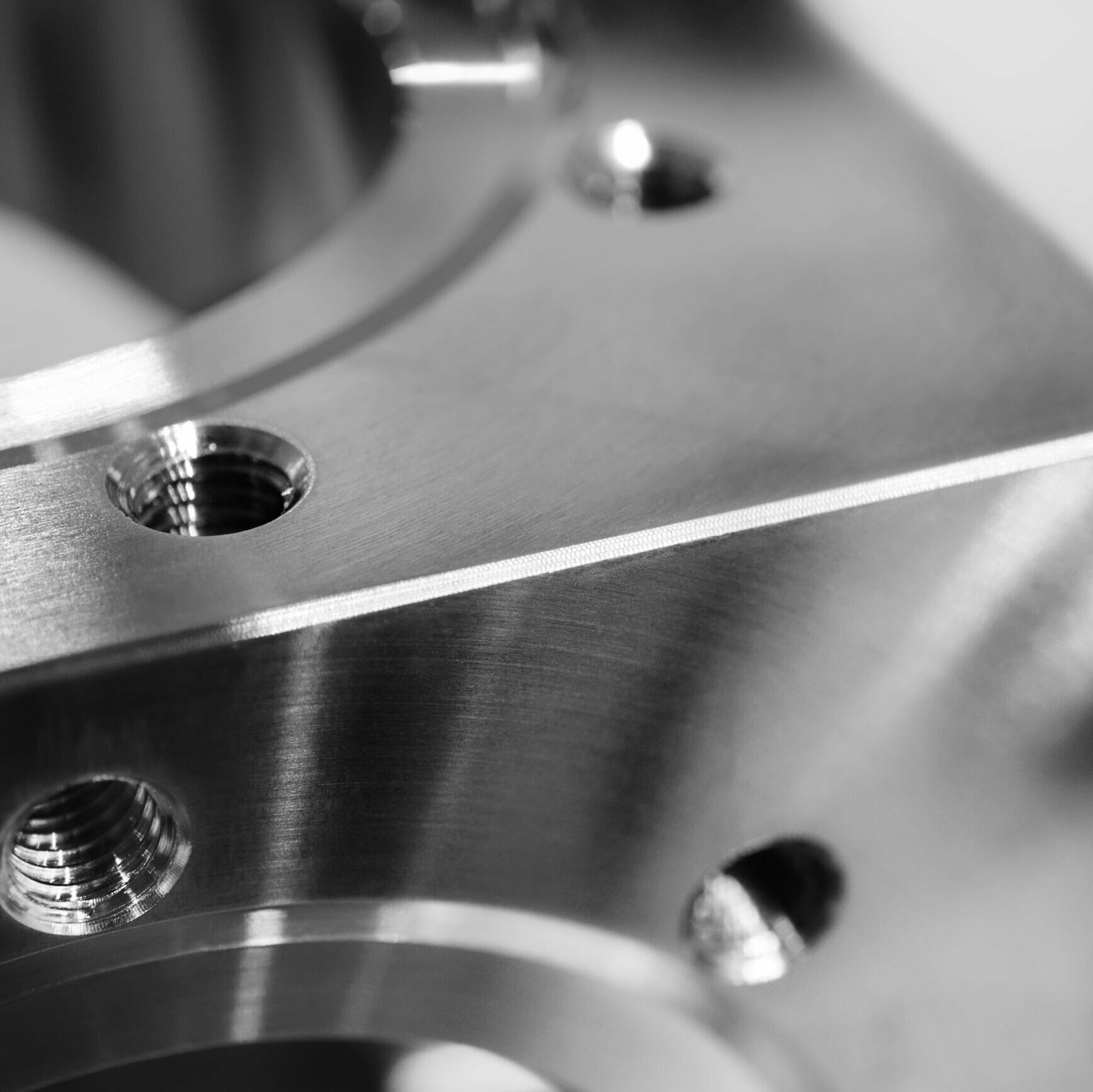

Precision Components. Delivered.

Instant Quotes for CNC-Machined Components

CNC milled parts are precision components that are used wherever highest quality is required. Through our powerful manufacturing network and instant quoting software, we connect our customers to the capabilities of over 3,000 CNC machines at the shortest possible time.

The problem with traditional quoting (and suppliers)

Traditional CNC quoting is slow because it depends on manual reviews, fragmented supplier responses, and unclear assumptions. Procurement teams lose days in RFQ follow-ups, quote clarifications, and apples-to-oranges comparisons across milling and turning suppliers. Engineers often get feasibility feedback too late, so tolerances, features, or setups trigger redesigns after the RFQ is already in motion. The outcome is predictable: longer lead times, more iterations, and higher total coordination cost before a single CNC part is ordered.

Procurement friction

Engineering friction

Why you should place your order with InstaWerk

Finding the right supplier for CNC milled parts is challenging. Each project is different, requires special machines or materials and must be delivered on time in the required quality. The best supplier for the prototype is probably not the right one for series production. Someone who can mill aluminium is not necessarily familiar with milling plastics. At InstaWerk, we manage a manufacturing network of hundreds of CNC fabricators to ensure we always have the right capacity for our customers’ projects. With our managed purchasing processes, we always ensure excellent conditions and reliable quality.

What we do

How we are different

f.a.q.

Instant Quoting for CNC Milling and Turning

Instant quoting gives fast, decision-ready pricing for CNC turning and CNC milling based on your CAD, quantity, material, tolerances, and finishing requirements. Below are the most common questions from procurement teams and engineers evaluating speed, accuracy, quality, and business impact.

An instant quote typically includes price, lead time, and the effort (material, quantity, tolerances, surface finish, inspection level). For CNC milling it accounts for features like pockets, walls, tool access, setups, and machining time. For CNC turning it factors in diameters, lengths, grooves, threads, parting operations, and secondary ops if needed. The quote is tied to a specific CAD revision, so changes remain traceable. InstaWerk’s AI based analysis algorithm inspects both 3D geometry (CAD) and the corresponding technical drawings (PDF).

Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur.

The biggest impact is cycle-time reduction: decisions shift from “waiting for quotes” to “acting on quotes”. That shortens development loops, reduces procurement workload per part, and accelerates market entry because cost and lead time are known earlier. Teams also gain better prioritization – you can stop spending engineering and sourcing effort on designs that are not cost-effective before you are deep into the RFQ process. Additionally, our instant quoting tools are linked to live capacities giving you instant access to 2.500+ machines.

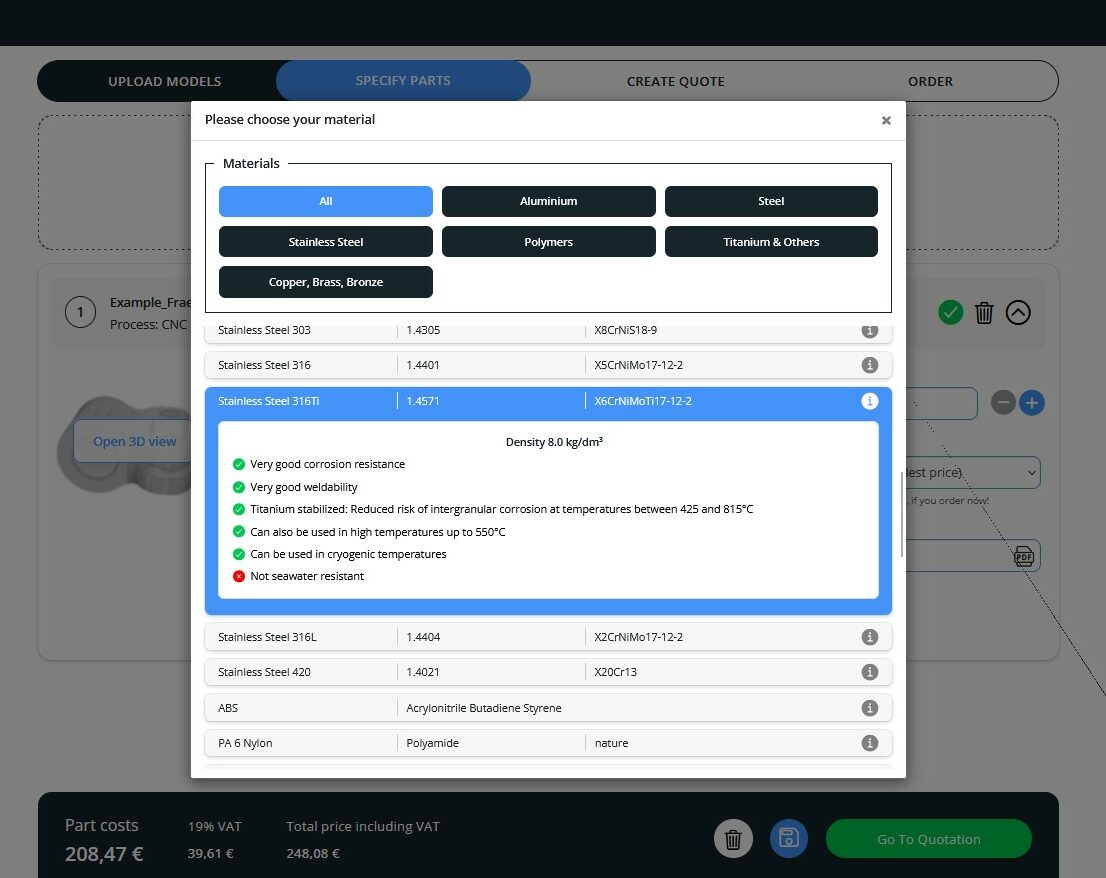

Engineers get earlier manufacturability clarity, which improves design-to-cost iteration while the part is still in CAD. You can quickly see which tolerances, radii, wall thicknesses, or setups drive cost and lead time for CNC milling and turning. That enables fewer late redesigns and cleaner handovers to procurement because requirements and quote assumptions are aligned from the start. Additionally, InstaWerk gives engineers access to unlimited process variants, 60+ materials, 40+ post treatments and 20+ quality control options. This variety enables engineers to develop next-level, advanced designs.

Instant quoting standardizes the intake (CAD + requirements) and reduces RFQ friction, clarifications, and chasing suppliers for missing details. It improves comparability because quotes follow consistent assumptions and are linked to revision-controlled data. Procurement gets a faster sourcing cycle with an audit-friendly trail – who requested what, when, for which CAD version, and under which requirements. Additionally, InstaWerk offers a OCI API for procurement teams, which want to link their ERP to InstaWerk.

Unit price is only one dimension (where we achieve an average of -19% of cost reduction compared to tradtional sourcing methods). Instant quoting reduces total sourcing cost by cutting internal coordination time, rework, and delay-driven expediting. Strategically, it supports flexibility and low fixed costs: you can scale up or down without CAPEX, avoid tying cash to machines and capacity, and keep teams focused on core value creation (product, engineering, customer delivery) instead of admin-heavy quote cycles. For many organizations, that combination is what unlocks faster development and easier market entry. Considering total cost of procurement, we achive an average cost reduction of -40%.

It means automation handles the fast baseline, and expert review steps when complexity, risk, or ambiguity is detected. Typical triggers are tight tolerances, challenging features, difficult materials, multi-op setups, or special inspection requirements. This approach keeps speed for standard parts, while maintaining engineering rigor for edge cases – so quotes remain realistic, manufacturable, and aligned with quality expectations (as used by InstaWerk). Besides our internal review, an engineering team is available for in-depth communicaiton before, during and after projects.

Quality starts with supplier qualification and process capability matching to the part requirements (material, tolerances, inspection level). For higher-risk parts, defined inspection plans, first-article checks, and documented measurements are standard practice. Traceability is maintained via revision control and clear specification capture, so there is no ambiguity between drawing intent and delivered part. Continuous feedback from produced parts closes the loop and improves future quoting and execution accuracy. All orders are checked internally on our Zeiss CMMs for quality. Additionally, InstaWerk is certified according to ISO 9001.

Access our unlimited CNC manufacturing ressources now:

Instant Quoting | Unlimited Manufacturing Capacity |

High Quality Exclusive Network | Short delivery times

Get in touch to run you CNC projects with us.

For urgent inquiries, complex manufacturing projects or other questions about your turned and milled parts, feel free to contact us at any time!

InstaWerk GmbH

Zettachring 12A, 70567 Stuttgart

Germany

Phone: +49 (0) 711 / 26 37 56 02

Email: support@instawerk.com