Manufacturing-on-Demand Platforms drive network effects

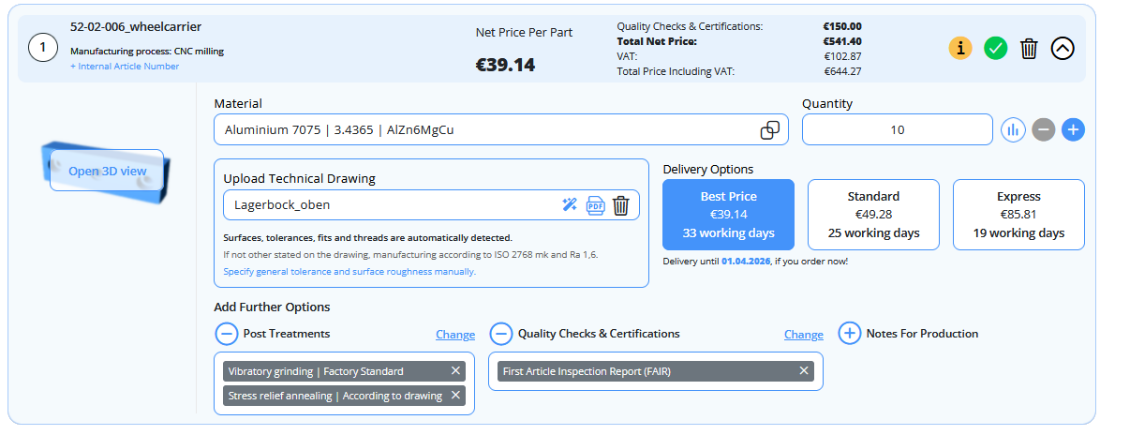

In the ever-evolving landscape of B2B commerce, the allure of the digital age extends its reach to the industrial sector. The concept of platform economics, driven by digital network effects, is now firmly rooted in industries such as manufacturing. A prime example in this realm is that of Manufacturing-on-Demand platforms. These two-sided platforms connect two distinct user groups – purchasers of CNC components and the manufacturing service providers producing these essential components.

One outstanding illustration of how sheer size isn’t the sole determinant of success in the realm of On-Demand platforms comes from the story of InstaWerk GmbH, based in Stuttgart, Germany. While others may prioritize “scaling at any cost,” Instawerk has carved a niche for itself by focusing on competence, quality, and trust as the building blocks of its Manufacturing-on-Demand platform.

We invite you to explore the full article to gain a deeper understanding of Instawerk’s remarkable journey and the transformative impact of the platform economy in the manufacturing sector. Below, you’ll find a summary of the original German article, allowing English-speaking readers to delve into the intricacies of Instawerk’s success story.

Here is what NC-Fertigung has to say about our manufacturing platform:

🔧 CNC is the backbone: InstaWerk’s success story revolves around a dedicated focus on CNC components (CNC-Turning, CNC-Machining) for three years.

💼 Platform Economy in B2B: The article explores how the forces of platform economics are reshaping the industrial sector through Manufacturing-on-Demand platforms.

🚀 Rapid Launch Amid Pandemic and War: InstaWerk’s journey began just before the COVID-19 pandemic struck, forcing them to adapt quickly to unforeseen challenges.

🤝 Direct Customer Engagement: InstaWerk’s emphasis on competence partnerships and communication with customers differentiates them in the competitive On-Demand platform market.

💰 Significant Cost Savings: By automating processes and intelligently bundling orders, Instawerk delivers approximately 20% cost savings for buyers compared to traditional procurement methods.