What this article says in brief:

- Rising financing costs for future investments and a tougher competitive environment are currently forcing industrial companies to save costs.

- In mechanical engineering, an increase in outsourcing can be observed – also due to an increasing shortage of skilled workers and the associated internal implementation weaknesses.

- In manufacturing, on-demand manufacturing platforms such as InstaWerk enable a cost-optimized purchasing solution “out of the box”

“Money is made in procurement”

Anyone who has tried to finance a property in recent months will have experienced the effects of the rise in interest rates very directly. The financing of (still) expensive real estate becomes unaffordable for many. Rising wage and material costs as well as the high interest rates press significantly on the budget.

The changing market environment is also felt in industry. This is because financing investments, R&D and market entry are becoming more expensive for companies. Cost optimization has become a crucial issue for companies in sectors such as mechanical engineering and scientific services. Those who want to invest in promising areas increasingly have to save the capital elsewhere.

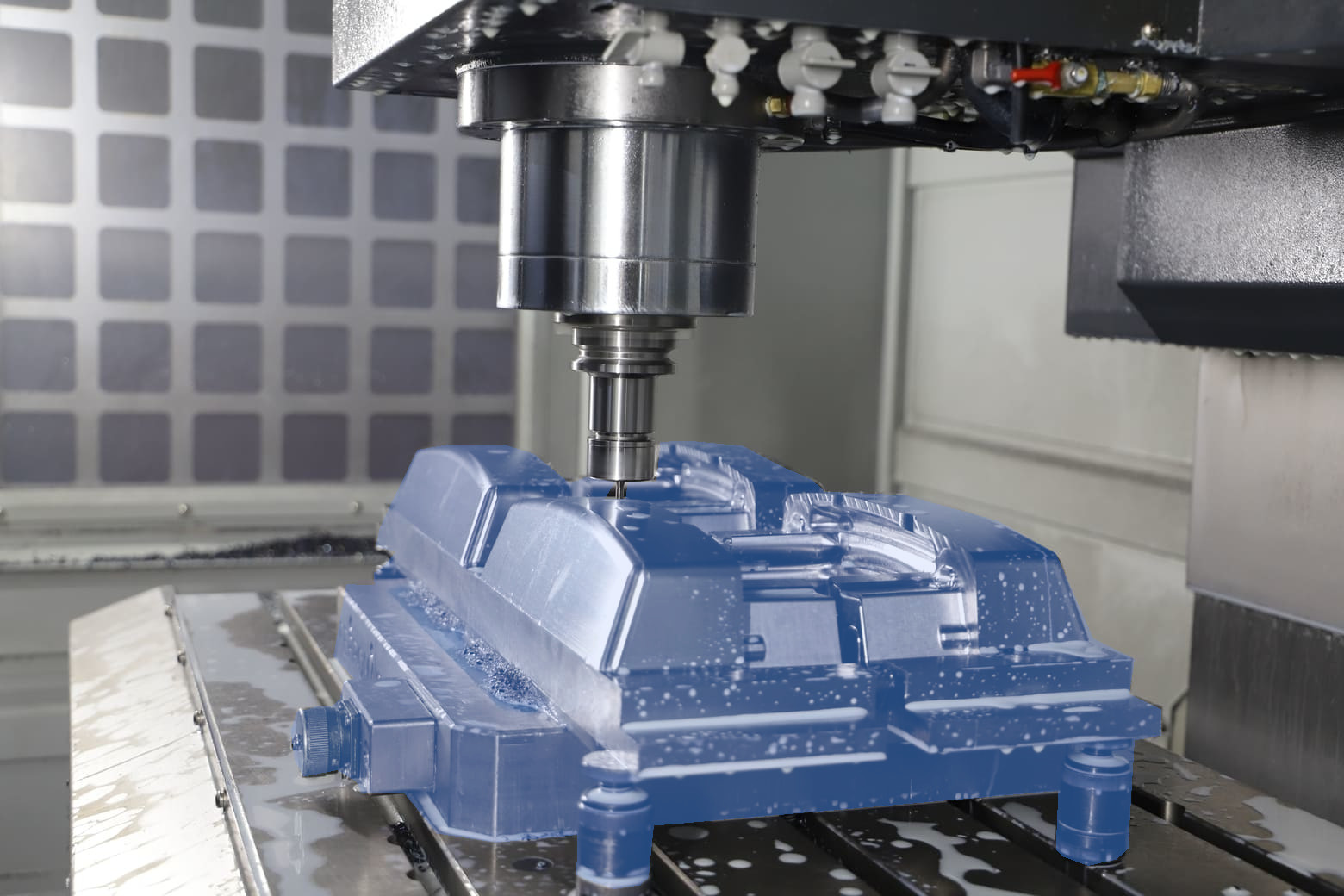

At the same time, the situation also offers companies the opportunity to increase their competitiveness, improve profitability and ensure long-term stability through effective cost optimization. In this article, we will address the increasing importance of cost optimization in industrial companies and show how the use of on-demand manufacturing platforms can reduce costs for CNC-manufactured parts (turned parts or milled parts).

“Do what you can do best, outsource the rest”

Companies in the mechanical engineering sector in particular are characterized by a high outsourcing rate. A study by the IMU Institute shows that increasing modularization and standardization are driving outsourcing even further. Automation in specialized companies, rationalization and the desire for increased productivity are also driving ever higher outsourcing rates.

Many of our customers also report that cost savings through outsourcing are currently high on their agenda. “We are currently focusing our capacities only on competition-critical components that require special know-how or machinery,” says Alexander Meyer, who heads the mechanical engineering company AlMay in Germany. “But even here, the shortage of skilled workers is forcing us to outsource in some cases“.

Make-or-buy decisions are a recurring topic of discussion and significantly determine the sourcing strategy and operational aspects in manufacturing. The more complex, comprehensive and long-term the make-or-buy decision becomes, the more strategic the decision. In doing so, companies often find themselves in a field of tension between capacity-balancing or even existence-securing measures.

However, a decisive target value is always the cost reduction and thus also the increase in future viability.

Make-or-buy decisions are a truncated perspective on reducing manufacturing costs. In order to optimize their own costs, companies basically have a number of options available to them when it comes to manufacturing and purchasing manufacturing services.

Manufacturing and production efficiency on the make side

The introduction of advanced manufacturing technologies and the implementation of lean principles can lead to significant cost savings. By minimizing waste and improving production planning, companies can reduce costs in areas such as material consumption, labor, and equipment maintenance.

Learn how to reduce the costs of your CNC-machined parts: Cost optimization.

Buy-side supply chain management:

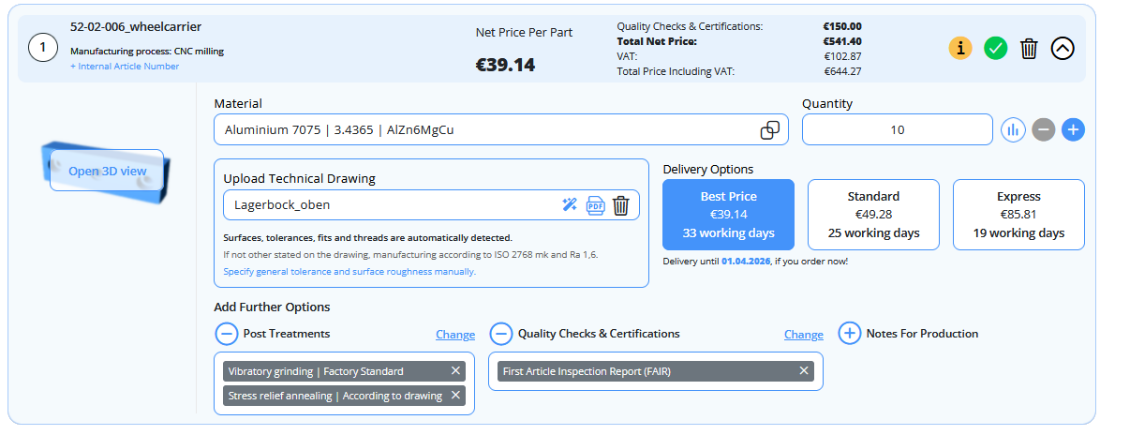

Streamlining procurement processes, managing supplier relationships and negotiating favorable terms are essential for cost optimization. In addition, the use of on-demand manufacturing platforms can significantly reduce the cost of CNC-manufactured parts. These platforms offer competitive pricing models, eliminate excess inventory and provide access to a wide range of materials and manufacturing capabilities. The core benefit is streamlining purchasing “out of the box.” Manufacturing platforms like InstaWerk specialize in sub-areas of manufacturing and build business processes and technologies around their specialty. Combined with increased purchasing power through order bundling and data-based contracting processes, manufacturing platforms make efficient procurement of manufacturing parts affordable for many companies.

The opportunities for technical cost optimization are largely considered to have been tapped. In recent years, however, digitization and globalization have revealed great potential in business model-based and organizational cost optimization.

On-demand manufacturing platforms: A game changer for cost optimization

On-demand manufacturing platforms like InstaWerk have revolutionized the way companies approach production and cost optimization. These platforms offer a range of benefits specifically tailored to reduce the cost of CNC-manufactured parts.

- Cost reduction through competitive pricing models: on-demand manufacturing platforms operate on a competitive basis so that companies can use absolutely competitive pricing mechanisms for themselves.

- Elimination of machinery, maintenance, inventory and storage costs: Traditional manufacturing often requires companies to maintain large inventories of CNC-manufactured parts and the necessary machinery. On-demand manufacturing platforms allow companies to produce parts on demand, reducing capex and eliminating excessive inventory and associated storage costs.

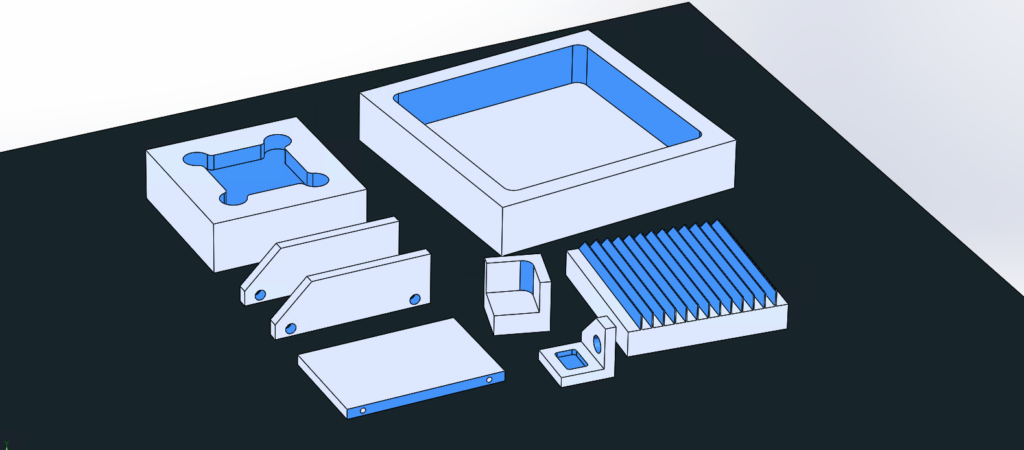

- Access to a wide range of materials and manufacturing options: On-demand manufacturing platforms offer a diverse selection of materials and manufacturing processes, allowing companies to choose the most cost-effective options for their specific needs, while also harnessing new technologies for their product development.

Strategies and tools for cost optimization with on-demand manufacturing platforms

An important success factor here lies in the selection of the right manufacturing platform. At InstaWerk, we have developed a number of unique selling points that have made us the preferred solution in mechanical engineering. We would like to briefly present these to you.

No reverse auctioning! Many platforms collect orders and award them in an underbidding competition to the manufacturer who makes the lowest offer. While this increases the platforms’ margins, it is not sustainable, as the cost pressure usually has a negative impact on quality. At InstaWerk, we bundle orders into packages and give them to suitable manufacturers in each case. The higher order volume allows us to build a stable supplier relationship, demand quality and maintain a long-term relationship. At the same time, we maintain a high level of data protection, as the design data is not made public. For our customers, this means security, reliability and high quality at reduced costs. Especially with turned and milled parts, the difference in quality quickly becomes apparent.

Specialization or all-in-one platform? We believe that specialization results in high quality and solution expertise. That is why we at InstaWerk have specialized in turned parts and milled parts. To this end, we offer comprehensive post-treatments and a broad materials portfolio. For sheet metal parts, welded parts or additively manufactured components, we are happy to help out when it comes to just a few parts. However, if you need a more in-depth solution, we will be happy to refer you to specialized manufacturers and platforms in this area.

Personal contact: Despite fast online ordering of your turned and milled parts, our team of engineers is available to you before and after the order for consultations, arrangements and coordination. Call us and see for yourself.

On-demand manufacturing combines efficiency and resilience

As industrial companies face increasing cost pressures, cost optimization has become a strategic imperative. The use of on-demand manufacturing platforms such as InstaWerk represents a transformative solution for reducing the cost of CNC machined parts.

By streamlining and digitizing supply chain management, improving manufacturing efficiency, and leveraging the power of on-demand manufacturing platforms, companies in the engineering, and other industries can achieve greater efficiency, improved profitability, and sustainable growth. Especially in uncertain times, cost optimization helps to stabilize the company and ensure competitiveness, even internationally.