OUR MISSION

Engineering Grade Manufacturing Capacities – it’s our DNA

InstaWerk builds on the roots of CIKONI – a high end engineering service known for enabling advanced multi material designs, from space bound hardware to next level machinery. That heritage shapes our mission: to give high end markets fast, dependable access to manufacturing capacity that meets engineered product standards. We combine online instant quotes with CNC milling and CNC turning delivered through a vetted partner network, technical review, and consistent quality assurance. The result is a sourcing experience that stays lean and digital while remaining uncompromising on specification, documentation, and delivery reliability.

Built for engineered products and the teams who develop them

WHAT WE DO

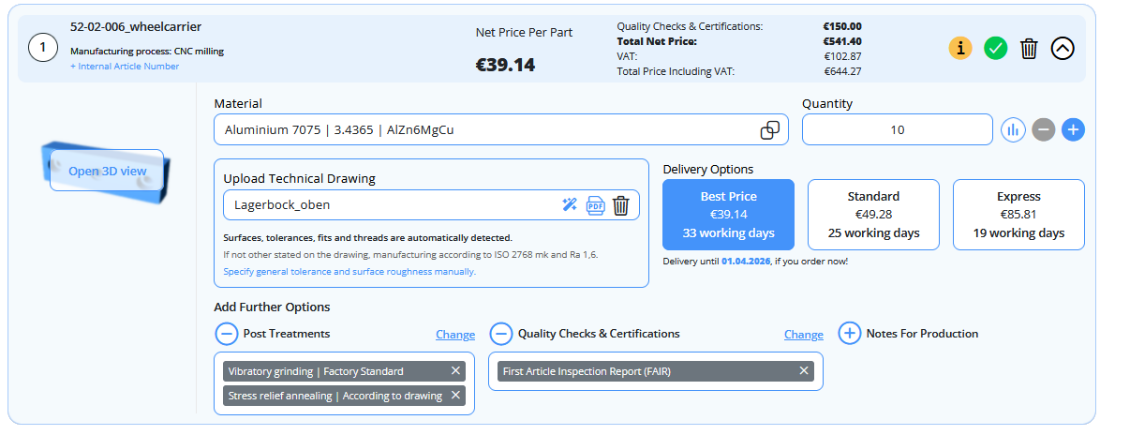

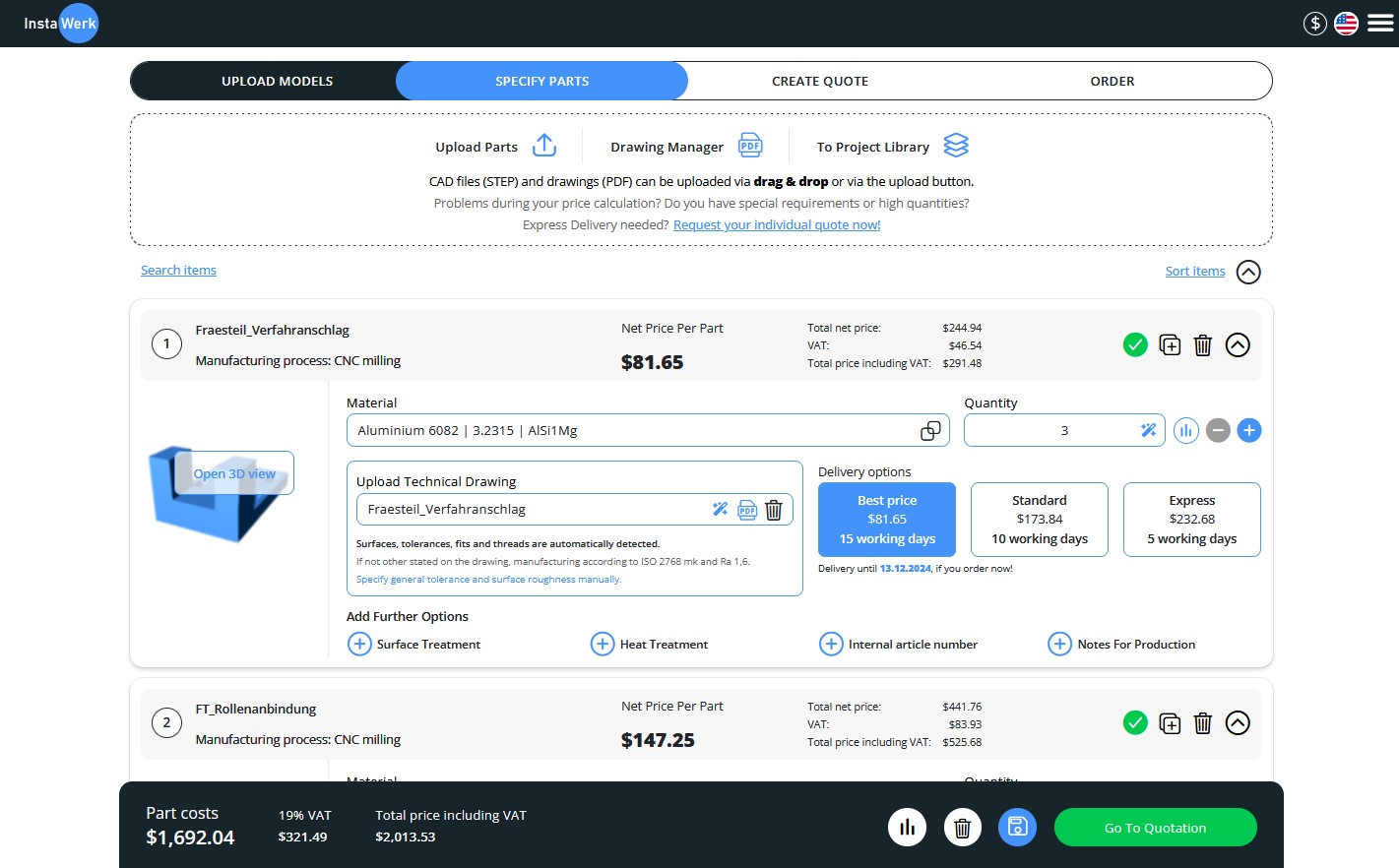

Instant access to high end CNC manufacturing capacity. At a reasonable cost.

InstaWerk is an online manufacturing platform for engineered parts. We deliver instant quotes and fast order execution for CNC milling and CNC turning, backed by technical review and a vetted partner network. From prototypes to series supply, we combine digital speed with engineering-grade quality assurance so teams can source parts with predictable lead times, transparent pricing, and reliable documentation.

CNC Machining reimagined.

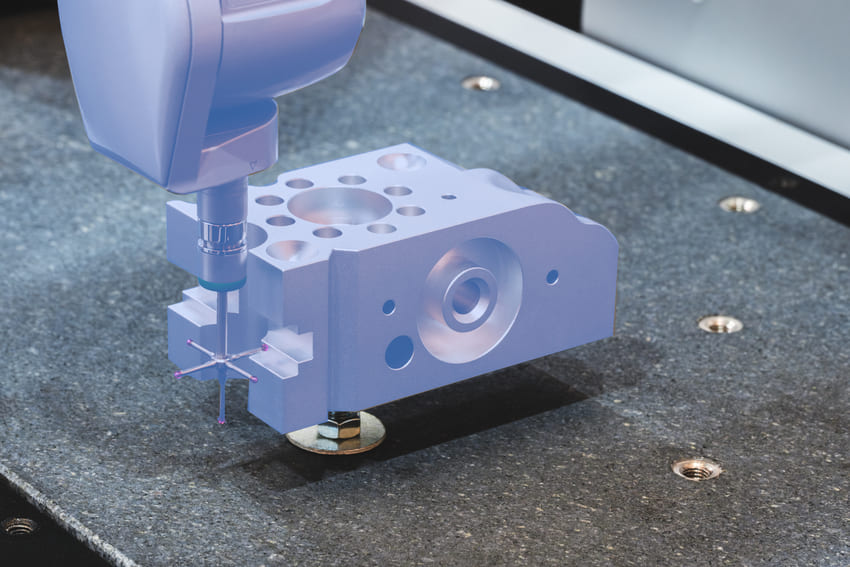

Quality as a Data Based System

Quality at InstaWerk is not a promise – it is a measurable system built on supplier data, audits, and repeatable controls. We work with an exclusive, pre-audited network rather than reverse-auction sourcing, and we continuously qualify performance, keeping top performers and removing underperformers. ISO 9001 certified processes and in-house inspection on a ZEISS CMM ensure every project is verified against specification before delivery.

An Exclusive Network

We keep our manufacturing network exclusive because engineered products demand consistency, not fluctuating capacity sourced through reverse auctions. Every supplier is pre-audited and integrated into a structured process with defined standards for capability, documentation, and reliability. This lets us build long-term performance visibility, continuously benchmark quality and delivery data, and maintain stable outcomes across projects. Exclusivity is not about limiting choice – it is about protecting predictability. We work with the best, develop them further, and remove underperformers to ensure every customer receives repeatable, engineering-grade results.

Rigid Control

Supplier quality control at InstaWerk is managed as a continuous, data-driven system rather than a one-time qualification. We run structured audits to validate capabilities, processes, and documentation standards, then track performance across every project. Quality results, delivery reliability, responsiveness, and deviation handling are measured and reviewed consistently. This creates a transparent benchmark of who performs under real production conditions. Top performers earn more projects and deeper collaboration, while recurring underperformance leads to corrective actions or removal from the network. The outcome is a supplier base that improves over time and delivers predictable results for engineered parts.

Certified Processes

ISO 9001 certification formalizes how we manage quality across the entire order lifecycle, from quoting and technical review to manufacturing, inspection, and delivery. It ensures our processes are defined, traceable, and continuously improved, with clear responsibilities and documented controls. For customers, this translates into predictable execution, consistent handling of deviations, and reliable documentation aligned with professional procurement standards. ISO 9001 is not a label for us – it is the operational framework that makes fast sourcing compatible with engineering-grade requirements.

In-house Control

In-house quality control adds an independent verification layer that goes beyond supplier self-checks. We use ZEISS coordinate measuring machines (CMM) to inspect critical dimensions and features against drawings and tolerances, ensuring objective measurement results. Every project receives defined inspection coverage, with consistent documentation and clear deviation handling when required. This enables repeatable part quality across suppliers, reduces risk for tight tolerance components, and gives engineering and procurement teams confidence that delivered parts match specification.

Our Company Story

From engineering challenge to manufacturing platform

InstaWerk started with a very practical problem: high-end engineering projects need to move fast, but sourcing manufacturing capacity rarely does. Our roots lie in CIKONI, where complex multi-material designs were developed for demanding applications, from space-bound hardware to advanced machinery. Turning these designs into hardware required parts that were precise, traceable, and repeatable – and it had to work from prototype iterations through to serial production.

Back then, sourcing parts at that level proved difficult to scale and hard to rely on. Suppliers were often unavailable or fully booked when timelines tightened, capacity shifted without notice, and even recurring parts could not be secured with consistent lead times. Quoting became an endless cycle of RFQs, follow-ups, and price comparisons, with too little transparency on whether quality, documentation, and delivery reliability would actually hold. The result was friction in the process: engineering teams slowed down, iteration loops stretched, and project schedules absorbed avoidable risk.

We decided to make it better. InstaWerk was built as a digital platform that combines instant quotes with controlled execution through an exclusive, pre-audited network, structured supplier performance management, ISO 9001 certified processes, and in-house inspection. The goal is simple: engineered products should not be delayed by sourcing – they should be accelerated by reliable access to CNC milling and CNC turning capacity.

Scalable CNC-Manufacturing with Quality in Mind

You cannot optimize the manufacturing triangle of time, cost and quality within one manufacturing facility. Therefore, we leverage our network of over 1,000 suppliers to realize the highest availability, attractive conditions and high-precision CNC components for you.

Reliable Manufacturing Capacities

By permanently tracking the reliability and quality of our suppliers, we ensure a highly resilient, reliable and high-quality network of CNC manufacturers.

From Prototypes to Serial Manufacturing

Whether it’s one piece or several thousand, at InstaWerk we ensure a high level of scalability so that you can securely and cost-effectively source your CNC-machined parts from development to market launch.

Quality, Quality, Quality

We are not just about accessibility and competitive offers. We are concerned with outstanding quality that is accessible and affordable. To achieve this, we develop in-depth quality standards and processes.

Unbeaten Conditions

By bundling orders into large order volumes, using network effects and streamlining all processes through digitalization, we offer unbeatable conditions for your CNC components.

Why InstaWerk?

InstaWerk delivers cost savings of up to 35% by combining competitive global sourcing with intelligent order bundling and an exclusive supplier network – in practice, customers often see around 19% lower pricing versus alternative suppliers for comparable CNC machined parts. Beyond piece price, the bigger lever is indirect cost: by standardizing specifications, consolidating vendors, and streamlining the full RFQ-to-PO workflow, teams can cut procurement effort by up to 90%. For advanced setups, procurement can be taken close to full automation via an OCI API integration, reducing manual touchpoints and cycle time while improving traceability. These savings do not trade off against quality, since parts are governed by rigorous quality control with inhouse Zeiss CMM measurement and ISO 9001-certified processes.

InstaWerk accelerates sourcing by turning RFQs into instant quotes and direct orders, cutting out the back-and-forth that typically slows down CNC machined parts procurement. Engineers get fast feasibility feedback and clear pricing upfront, while procurement benefits from a standardized, auditable ordering flow that reduces coordination overhead. Lead times start from 3 days for many CNC milled parts and CNC turned parts, helping teams keep prototypes and production ramps on schedule. For urgent needs, express delivery can be arranged from 24 hours on request, making last-minute design iterations and critical spares significantly easier to manage.

InstaWerk ensures consistently high quality for CNC Machining by combining ISO 9001-certified processes with rigorous, standardized quality gates for CNC machined parts. A dedicated in-house quality hub with Zeiss CMMs and additional high-end inspection equipment enables reliable verification of critical dimensions on CNC-milled parts and CNC-turned parts, including tight tolerances and feature-level checks. Supply is secured through an audited, exclusive supplier network, so only qualified partners manufacture your CNC machined parts to defined standards. Continuous, data-based monitoring of supplier performance adds an additional control layer, improving repeatability across batches and reducing risk for engineers and procurement teams alike.

InstaWerk focuses on what matters most for demanding hardware teams: CNC Machining – specifically CNC Milling and CNC Turning – instead of spreading attention across unrelated processes. This specialization enables eye-level, shoulder-to-shoulder communication with engineers and procurement, and equally clear alignment with suppliers, because every discussion is grounded in the realities of CNC-milled parts and CNC-turned parts. Within this domain, you get in-depth engineering support and practical process know-how to de-risk specifications, tolerance stacks, and functional requirements for CNC machined parts. With 60+ materials and 40+ post treatments, the portfolio stays highly versatile while remaining fully optimized for CNC Machining outcomes.

InstaWerk runs on software that is self-developed, self-hosted, and self-managed, which means every data flow in the ordering process is under direct control – from CAD upload to delivery of CNC-milled parts and CNC-turned parts. This reduces uncertainty about where CAD files, drawings, and order data are processed, and it supports clearer governance for engineering and procurement workflows around CNC machined parts. Strict access and data control mechanisms are in place to minimize exposure and enforce consistent handling across projects and stakeholders. The approach is designed to meet data protection law requirements and to provide a dependable foundation for companies with elevated confidentiality, compliance, or IP protection standards.

InstaWerk supports CNC Machining projects end-to-end with in-house engineering and production experts based in Germany, helping teams specify and source CNC machined parts with confidence. This experience is built on working with more than 2,500 customers across a wide range of industries, from fast-moving product development to regulated environments with strict documentation needs. A dedicated support engineer is available before, during, and after production, ensuring continuity across quoting, design clarification, supplier coordination, and delivery of CNC-milled parts and CNC-turned parts. The result is faster decisions, fewer misunderstandings, and lower project risk for both engineers and procurement.

Access our unlimited manufacturing ressources now:

Instant Quoting | Unlimited Manufacturing Capacity |

High Quality Exclusive Network | Short delivery times