1. Get an online quote for CNC Machining. Instantly.

Upload your CAD and drawing package to get live pricing and lead times in seconds. Adjust materials, quantities, and requirements, then order when you are ready.

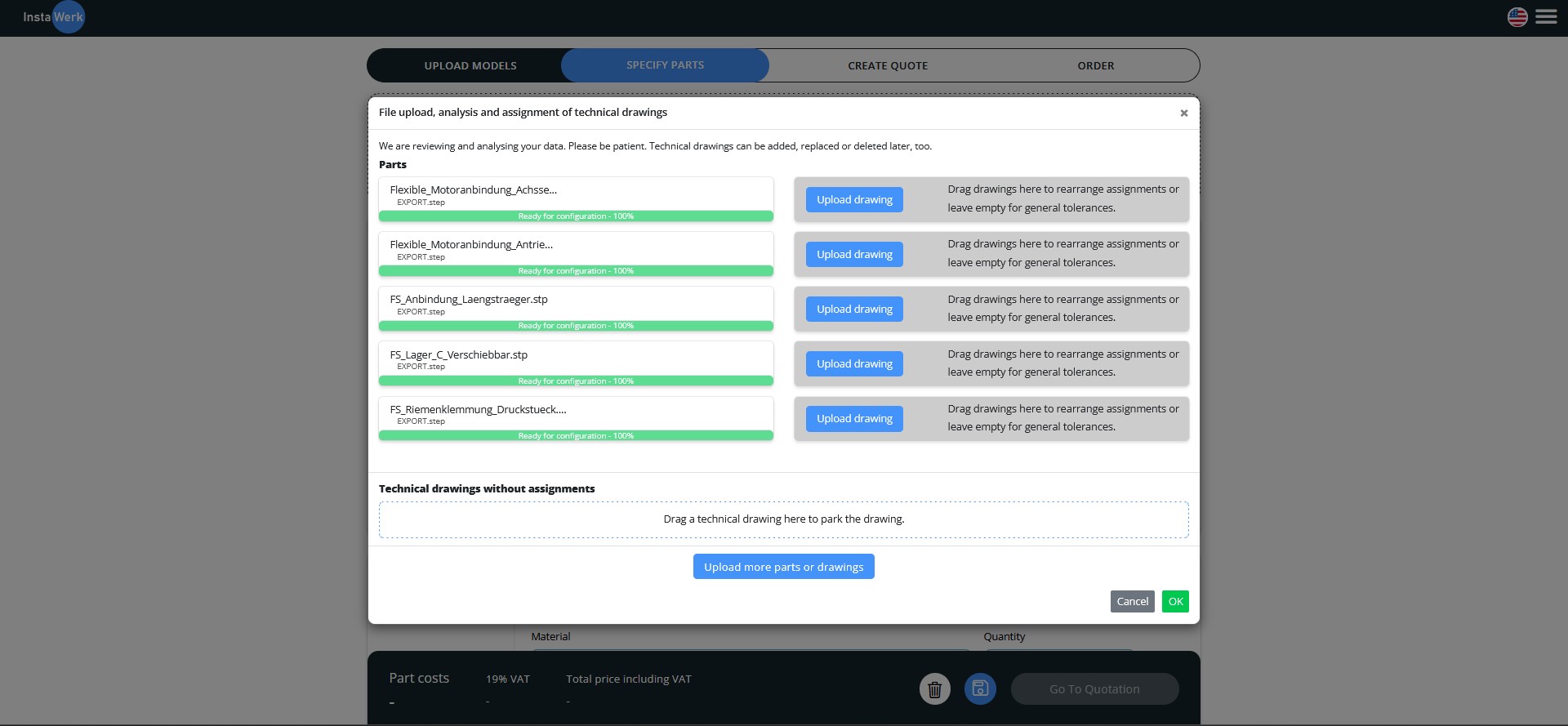

Upload your CAD + Drawings

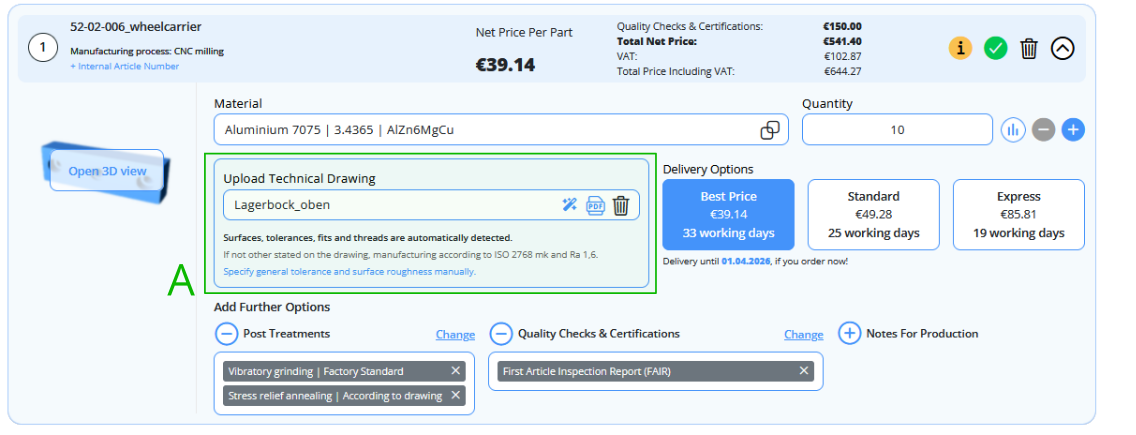

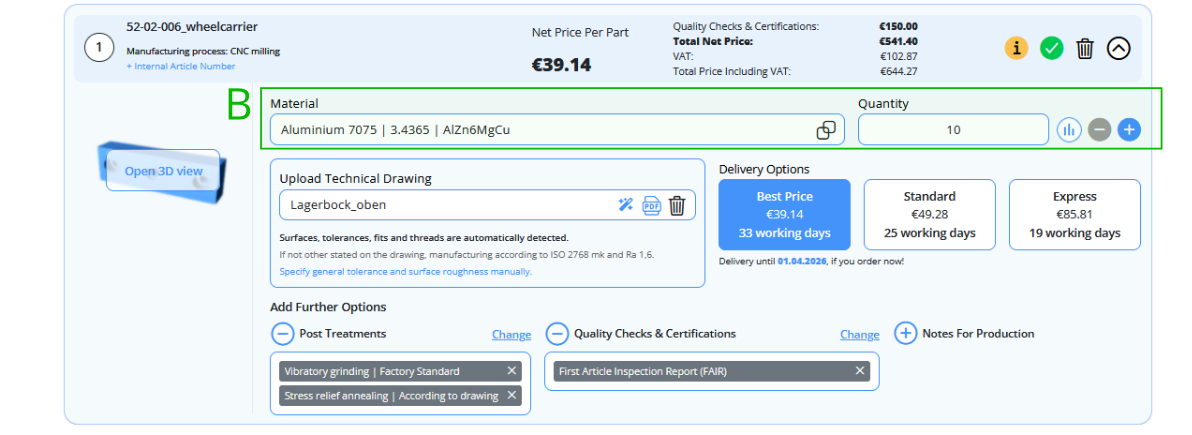

Upload your CAD files and technical drawings in one step. Add quantities, materials, finishes, and any critical notes so manufacturing requirements are unambiguous from the start.

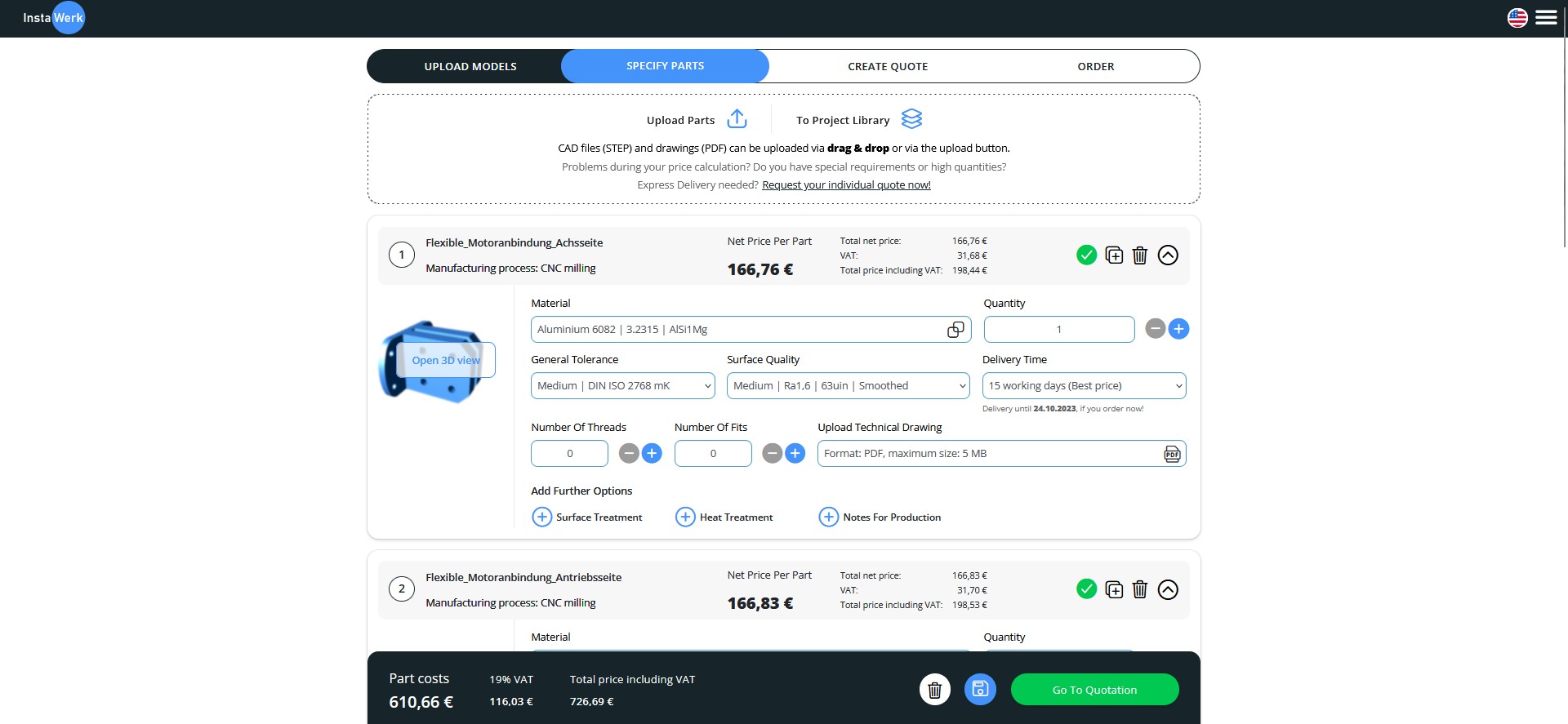

Get an instant quote.

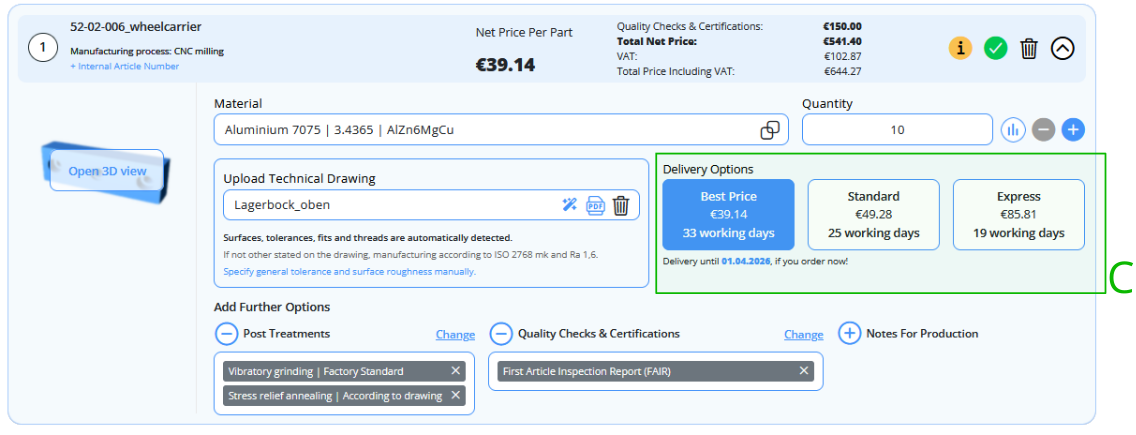

Receive an instant quote with transparent pricing and lead-time options. Every change is priced instantly, so you can define options before release to production.

Receive your parts.

After approval, production runs through defined quality checks with end-to-end tracking. Your parts ship directly to your site, with engineering support available whenever clarification is needed.

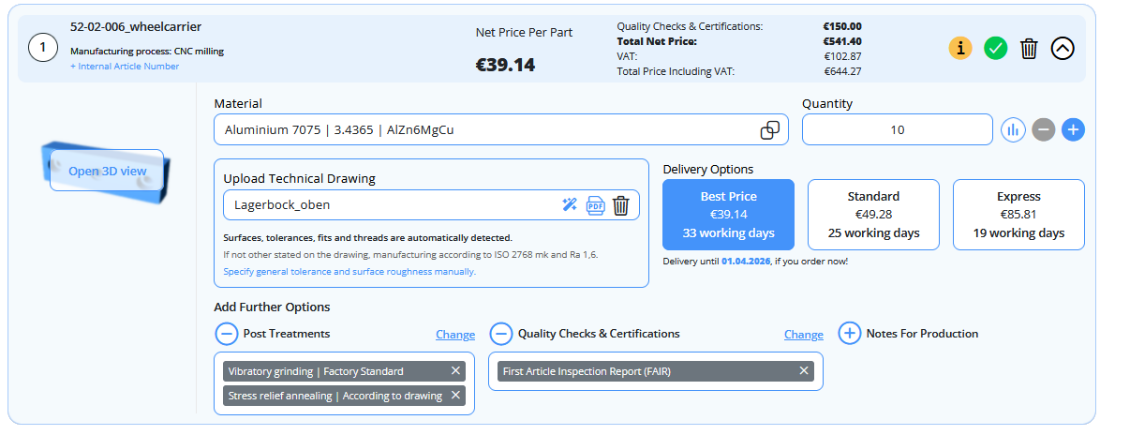

Configuring your machined parts in 4 quick steps

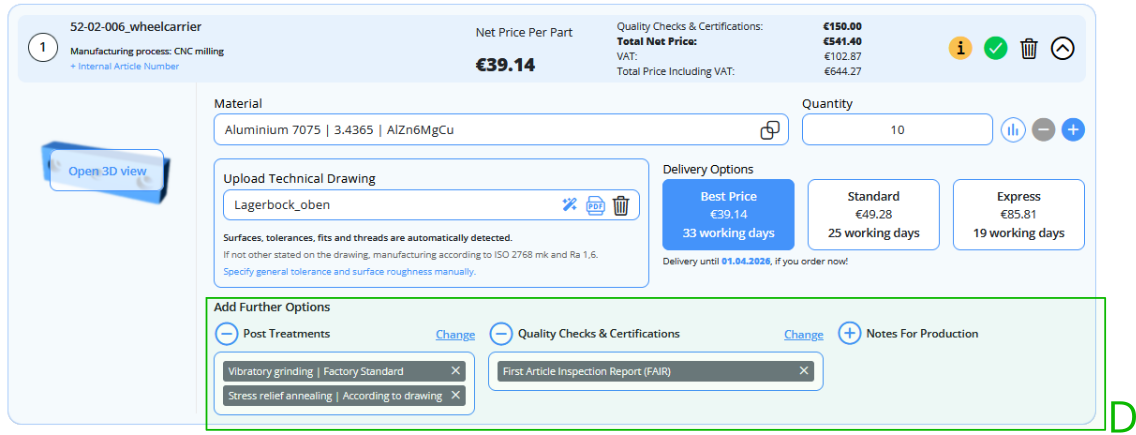

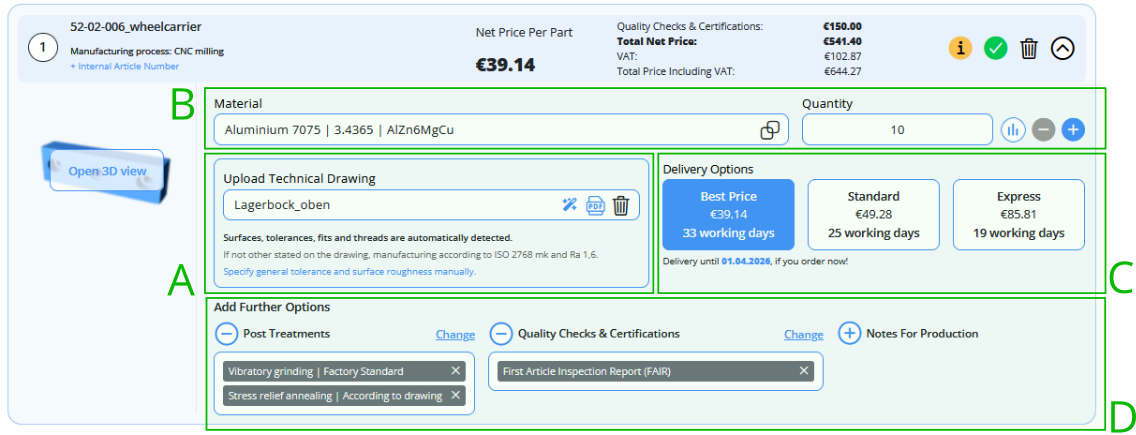

Configure each part directly online. Add drawings, select material and quantity, set your lead time, then define finishing and inspection requirements – pricing and delivery update instantly as you adjust options.

Start with a complete, production-ready setup for each part. Review price options, confirm key specs, and see total price, lead time, and quality scope in one place before you proceed.

2. Have it manufactured – in a prequalified network

Audits & Supplier Onboarding

Every CNC machining partner is qualified before joining our network. We verify CNC milling and CNC turning capabilities, inspection equipment, and documentation standards. Only suppliers meeting defined quality control requirements are activated for orders.

Continous Monitoring

Quality is continuously tracked, not checked once. We monitor delivery reliability, defect rates, and recurring issues across CNC milling and CNC turning. Performance data and inspection feedback keep processes stable and predictable over time.

Inhouse Quality Control Approach

InstaWerk applies a structured quality control process to every order. Inspection scope is defined per part, with optional documentation such as certificates of conformity and material certificates. Dimensional checks and surface finish requirements stay aligned with your drawings and specs.

How we audit our suppliers

InstaWerk works with CNC machining suppliers that operate a defined quality management system with clear roles, responsibilities, and measurable objectives. Relevant certifications (ISO/AS, where applicable) are verified during onboarding. This creates a consistent baseline for CNC milling and CNC turning quality control across the network. InstaWerk is certified to ISO 9001.

Traceability is built into our CNC machining workflow from material receipt to shipment. Suppliers maintain records for raw material in and out, quantities, and key manufacturing process steps. Requirements also extend to subcontractors, ensuring CNC milled and CNC turned parts remain traceable across the full supply chain.

InstaWerk expects responsible working conditions across the supply network. Supplier onboarding checks safe hiring practices, workplace protections, and compliance with non-discrimination standards. Fair working hours and appropriate remuneration are part of the baseline expectations for qualified manufacturing partners.

Incoming materials are identified and verified before they enter production. Suppliers document incoming quality control checks and maintain records that link material batches to CNC machining orders. FIFO handling supports stable processing and reduces mix-ups across CNC milling and CNC turning jobs.

During production, orders are clearly identified and tracked to prevent part mix-ups. Machines and manufacturing equipment are validated for the required CNC machining process, with defined quality controls executed during CNC milling and CNC turning. Packaging is handled to protect parts and keep order traceability intact.

Before a supplier is approved for CNC machining, Instawerk verifies required registrations, licenses, and legal standing. We run background checks and sign formal agreements that define compliance, confidentiality, and quality control responsibilities. This creates a reliable framework for CNC milling and CNC turning orders from day one.

Each new supplier is validated through an Instawerk factory audit covering quality management performance plus environmental and social compliance. We assess the site against network qualification criteria, align expectations for CNC machining quality control, and document how collaboration works in practice. During onboarding, supply chain managers closely monitor initial CNC milling and CNC turning orders, supported by on-site checks before and after production when needed.

Why InstaWerk?

InstaWerk delivers cost savings of up to 35% by combining competitive global sourcing with intelligent order bundling and an exclusive supplier network – in practice, customers often see around 19% lower pricing versus alternative suppliers for comparable CNC machined parts. Beyond piece price, the bigger lever is indirect cost: by standardizing specifications, consolidating vendors, and streamlining the full RFQ-to-PO workflow, teams can cut procurement effort by up to 90%. For advanced setups, procurement can be taken close to full automation via an OCI API integration, reducing manual touchpoints and cycle time while improving traceability. These savings do not trade off against quality, since parts are governed by rigorous quality control with inhouse Zeiss CMM measurement and ISO 9001-certified processes.

InstaWerk accelerates sourcing by turning RFQs into instant quotes and direct orders, cutting out the back-and-forth that typically slows down CNC machined parts procurement. Engineers get fast feasibility feedback and clear pricing upfront, while procurement benefits from a standardized, auditable ordering flow that reduces coordination overhead. Lead times start from 3 days for many CNC milled parts and CNC turned parts, helping teams keep prototypes and production ramps on schedule. For urgent needs, express delivery can be arranged from 24 hours on request, making last-minute design iterations and critical spares significantly easier to manage.

InstaWerk ensures consistently high quality for CNC Machining by combining ISO 9001-certified processes with rigorous, standardized quality gates for CNC machined parts. A dedicated in-house quality hub with Zeiss CMMs and additional high-end inspection equipment enables reliable verification of critical dimensions on CNC-milled parts and CNC-turned parts, including tight tolerances and feature-level checks. Supply is secured through an audited, exclusive supplier network, so only qualified partners manufacture your CNC machined parts to defined standards. Continuous, data-based monitoring of supplier performance adds an additional control layer, improving repeatability across batches and reducing risk for engineers and procurement teams alike.

InstaWerk focuses on what matters most for demanding hardware teams: CNC Machining – specifically CNC Milling and CNC Turning – instead of spreading attention across unrelated processes. This specialization enables eye-level, shoulder-to-shoulder communication with engineers and procurement, and equally clear alignment with suppliers, because every discussion is grounded in the realities of CNC-milled parts and CNC-turned parts. Within this domain, you get in-depth engineering support and practical process know-how to de-risk specifications, tolerance stacks, and functional requirements for CNC machined parts. With 60+ materials and 40+ post treatments, the portfolio stays highly versatile while remaining fully optimized for CNC Machining outcomes.

InstaWerk runs on software that is self-developed, self-hosted, and self-managed, which means every data flow in the ordering process is under direct control – from CAD upload to delivery of CNC-milled parts and CNC-turned parts. This reduces uncertainty about where CAD files, drawings, and order data are processed, and it supports clearer governance for engineering and procurement workflows around CNC machined parts. Strict access and data control mechanisms are in place to minimize exposure and enforce consistent handling across projects and stakeholders. The approach is designed to meet data protection law requirements and to provide a dependable foundation for companies with elevated confidentiality, compliance, or IP protection standards.

InstaWerk supports CNC Machining projects end-to-end with in-house engineering and production experts based in Germany, helping teams specify and source CNC machined parts with confidence. This experience is built on working with more than 2,500 customers across a wide range of industries, from fast-moving product development to regulated environments with strict documentation needs. A dedicated support engineer is available before, during, and after production, ensuring continuity across quoting, design clarification, supplier coordination, and delivery of CNC-milled parts and CNC-turned parts. The result is faster decisions, fewer misunderstandings, and lower project risk for both engineers and procurement.

Access our unlimited manufacturing ressources now:

Instant Quoting | Unlimited Manufacturing Capacity |

High Quality Exclusive Network | Short delivery times