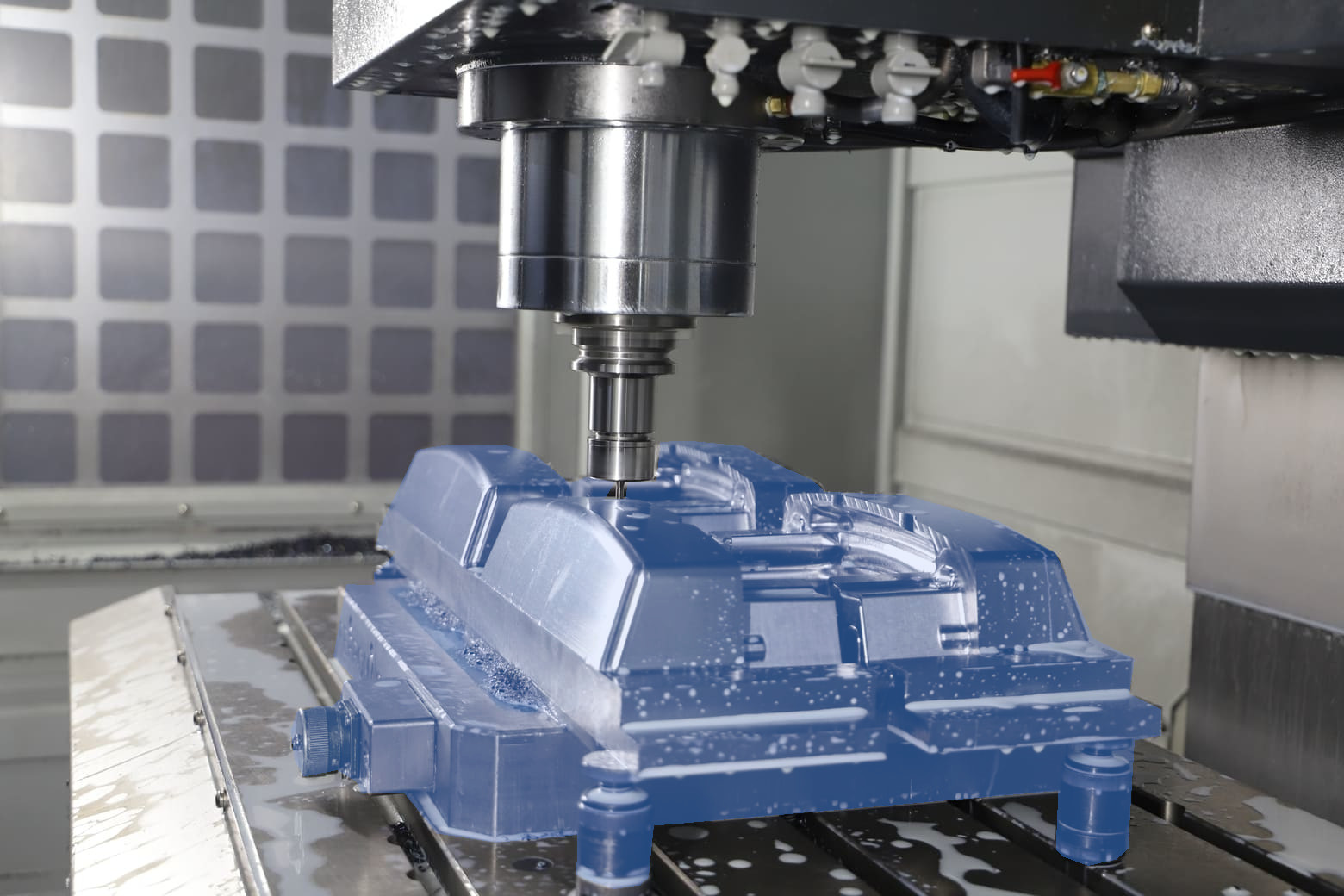

CNC machining technology is used for various projects and offers multiple advantages to firms operating in different sectors. While being a standard process in mechanical engineering, CNC machine tools builders constitute a market size of roughly 50 Billion US dollars, offering ongoing innovations to the players in the market.

1. Hybridization of CNC-Manufacturing with additive Technologies

Subtractive CNC machining and additive 3D printing are two distinct processes. CNC machines remove materials from a workpiece. 3D printing involves building three-dimensional objects one layer at a time. Even so the working principle is contrary, both processes can be combined efficiently.

A range of machine builders have embraced "hybrid manufacturing," which combines CNC milling and turning with additive methods. The number of businesses investigating how CNC machines and 3D printers might be coupled to expedite the completion of projects is growing.

Tolerances of less than 0.01 millimeters can be achieved with CNC-machines, making them ideal for applications in which precision is essential. However, the accuracy of a 3D printer is in the range of 0.1 millimeters, which is one reason why additive manufacturing are widely used for prototypes. Prototypes may be printed out on a 3D printer. Following that, a CNC machine will be able to finish the product.

This approach has been implemented by DMG-Mori from Bielefeld, Germany. Their hybrid AM/CNC machine LASERTEC 125 DED hybrid combines additive and subtractive manufacturing into one machine cell. As the printing and machining heads can be interchanged and the base system offers a five-axis degree of freedom, complex geometries can be manufactured with high end precision. During the process an infrared thermal camera is inspecting the additive built up process and enables adaptive process control.

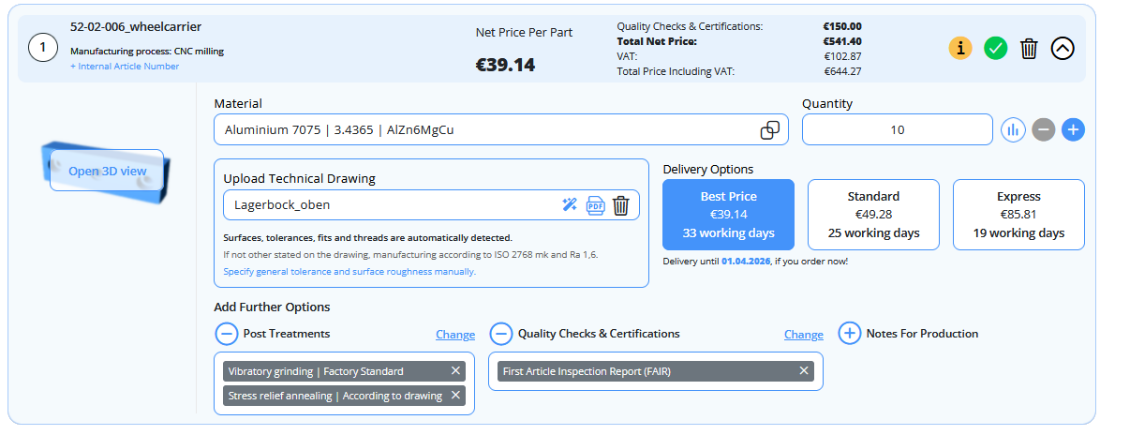

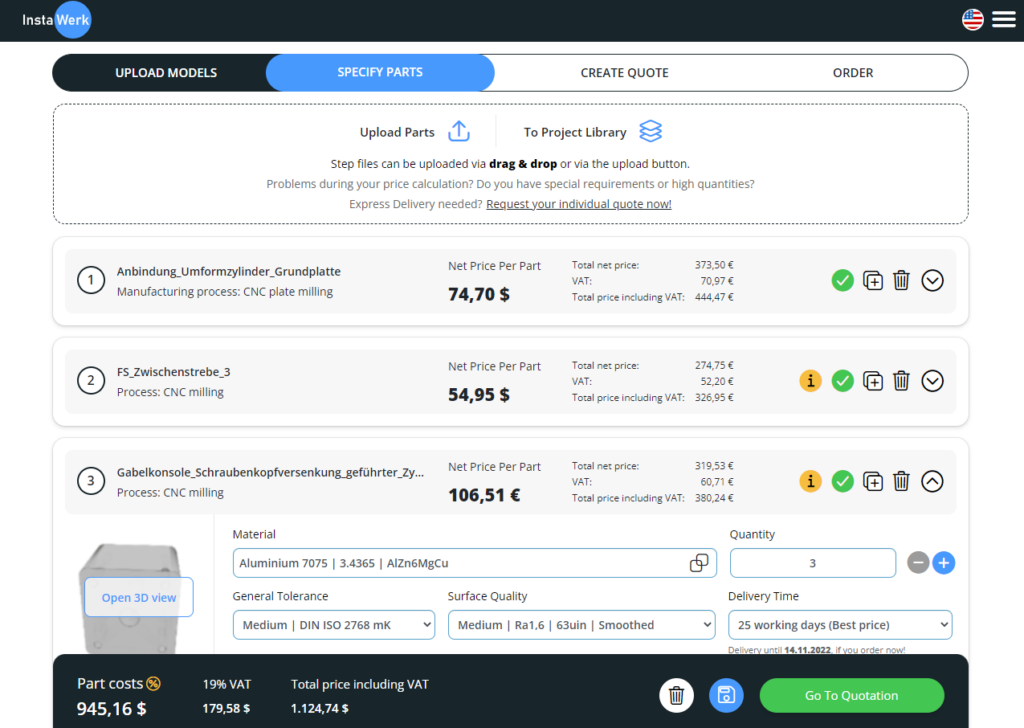

2. On-Demand Manufacturing and Instant Quoting

A strategy in manufacturing known as "on-demand manufacturing" or "cloud manufacturing" has evolved. It is starting to disrupt the supply chain sector and has been accelerated clearly by Corona, the Ukraine war and supply issues with China. The term "on-demand manufacturing" describes a production method in which products are made just when demanded and in the necessary amounts. Traditional manufacturing, on the other hand, necessitates having expensive in-house production machines, producing goods in big numbers or relying on local manufacturing partners. On-demand manufacturing reduces capital investment, increases speed of procurement and improves resilience.

Several other factors, such as reduced part costs for CNC-machined parts and fast ordering due to instant quoting software are all contributing to the widespread acceptance of on-demand manufacturing. The argument for on-demand manufacturing is solid for businesses of all sizes. Consumers, corporations, and the natural environment may all get rewards from the procedure. Here are three major benefits that companies may expect from on-demand manufacturing:

- Decreased Manufacturing Expenses

- Agile Operations due to faster procurement and higher availability of various manufacturing technologies

- Easy access to global manufacturing ressources

InstaWerk from Stuttgart, Germany is a leading example of a digitalized CNC machining service provider.

3. Improvement of CNC Machining using Digital Twins

Digital twins are used to get a deeper understanding of how equipment and processes are operating. In most cases, digital twins are a accurate representation of their respective physical counterparts. In addition, although a simulation will often only display a single function, digital twins are more generalistic. They may provide information on several different processes all at the same time.

According to a recent article by Vishnu et al. digital twins in CNC-manufacturing can be implemented in the process planning stage, in the machining stage, for model building and for feedback loops. Based on various input parameters like feed rate, tool material, clamping force and wear rate, the authors were able to implement a surface roughness predictive model by generating a toolpath, executing experiments and feed the results to their models utilizing Support Vector Machine (SVM), Gaussian Process (GPR) and a Fully connected deep neural network (FCDNN). Consequently the model was successfully tested on new parameters.

These digital twin technologies enhance the decision-making making capability of process planners and machine operators for controlling the machining parameters at process planning stage and machining stage

4. Greater Investments in Automation

CNC machining processes are also influenced by automation in several different ways. In recent years, it has been increasing relevance, and that tendency will continue into the foreseeable future. While automation has been focused on the individual machining. A partnership between Mitsubishi and AIST led to the developing of a CNC machine solution that integrates AI and automated processes. It is an error correction method that uses artificial intelligence to estimate disparities between the present position of a CNC machine and its command value.

According to the results accomplished by tests, the accuracy of this strategy was increased by 51% compared to the non-AI solutions. This technology can also make improvements during dynamic machining, which helps save time while maintaining a high level of quality.

But the trend is going towards factory wide automation with the ultimate goal being “light out factories”. The advantages are straight forward: Labour cost saving, increased productivity and consistency. Starting with a camera-controlled robotic cell to load or unload CNC machines autonomously, factories will build additional stations to manage the marking, measuring, and packaging to leverage the advantages of autonomous factories.

While developing light-out factories, a couple of question have to be answered:

- Is the current part mix a right fit for automated manufacturing?

- Are the right machine features, tools and control system in place to allow lights-out machining factories?

- How shall automation friendly and flexoble tooling and workholding be achieved?

- How is remote monitoring, maintenance and problem solving provided?

- How to automatically detect erros like machine stoppage, tool failure or software failures?

A well-executed lights-out machining factory has huge potential to revolutionize the way machining gets done, but shops must be willing to make the investment and improve their processes. Obviously this high level of automation is only suitable for high volume production of recurring parts and less for prototypes and small scale production volumes which require manual optimization, creativity and pragmatism.

5. Developing Environmentally Sustainable Solutions

CNC manufacturers will need to start tracking and lowering the carbon emissions made by their production processes and supply chains to satisfy customers' rising demand for items manufactured in a more environmentally responsible manner. New or redoubled attempts to cut carbon emissions by CNC machining services will continue to meet consumer demand, support from corporate responsibility, and government agencies rules and regulations.

Manufacturing company will need to use production and supply data chains that are easier to access to conduct a more accurate assessment of the carbon footprints left by their products and explore new ways to produce and transport their wares in a more environmentally responsible manner.

6. Growth of Manufacturing as a Service

MaaS (manufacturing as a service) has only lately found its way into the CNC machining industry. Still, you can anticipate it will acquire greater adoption as time goes on. In a few words, MaaS uses networked resources to accomplish manufacturing activities by making them available through a digital interface.

MaaS can give businesses increased flexibility, increased productivity, increased agility, and cost savings via lower labor expenditures. As the repercussions of the pandemic continue, it is safe to predict that businesses who wish to reduce their expenses and run on tight budgets would, at the very least, investigate the idea of contracting to a CNC-powered MaaS service.

InstaWerk is one of the leading providers of Manufacturing as a Service (MaaS) solutions. We operate from Germany, but supply the whole world. Our specialization is in the production of turned parts and milled parts. Through our instant calculation of component costs, we can make the benefits of on-demand manufacturing easily and transparently available to our customers.

From Theory to Practise: Putting innovations to work

We regard it as our mission to make innovative processes, trends and new solutions accessible to our customers. Whether hybrid processes, sustainability or network effects of the platform economy: we will continue to make everything usable for our customers. The easiest way to try out these new technologies? Register now and get started!