Automation and Digitization in Procurement

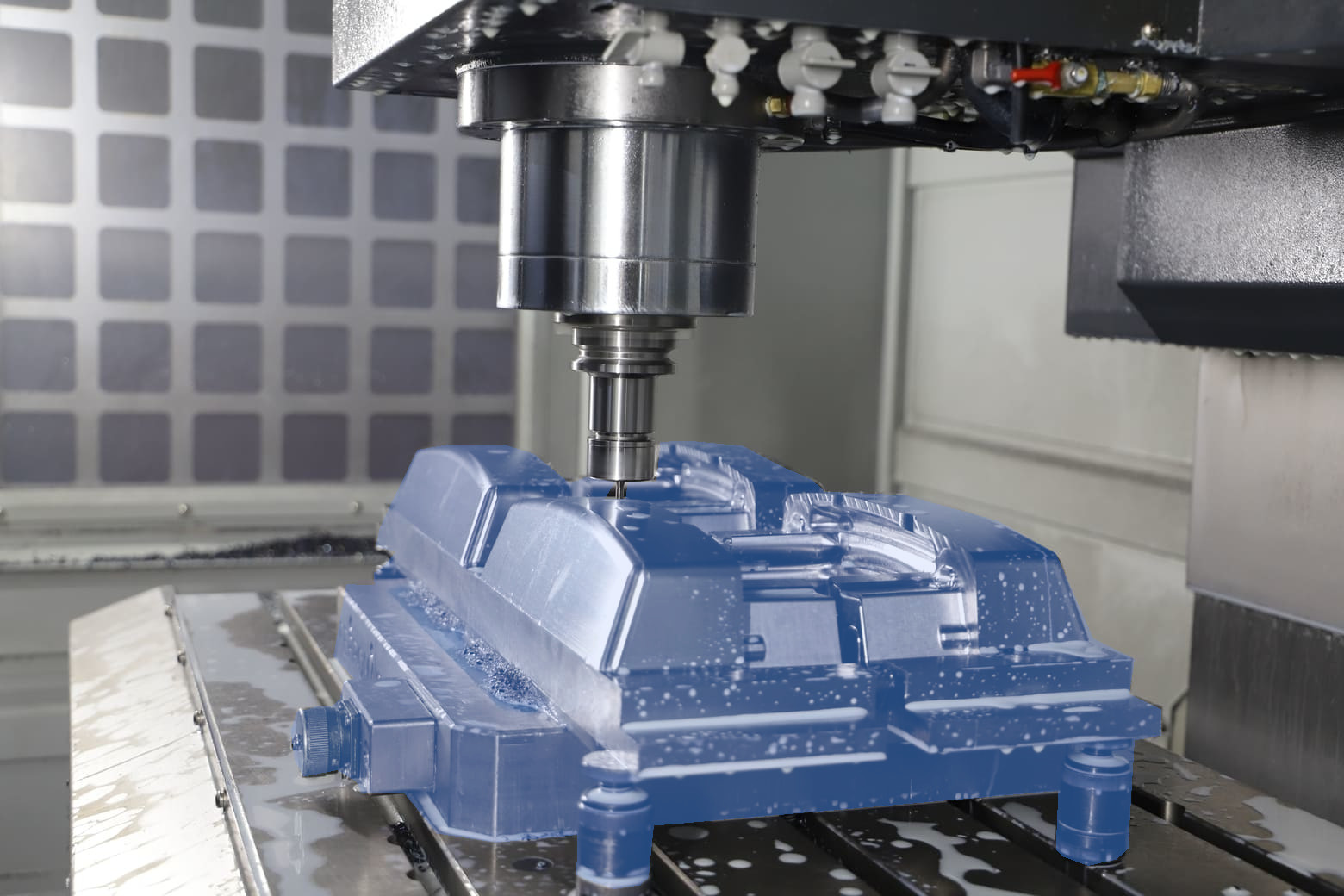

Automation and digitization are pivotal for industrial firms striving to maintain competitiveness. Purchasing industrial components like turning and milling parts is no exception. Leveraging digital procurement solutions not only optimizes processes but also enhances employee satisfaction and competitiveness. Digital workflows automate the entire procurement process from inquiry to delivery, leading to significant cost savings and ensuring quick availability of precision components for development and production.

Challenges in Ordering Custom Machined Parts

Ordering custom turning and milling parts presents unique challenges. Each part is unique, requiring specifications from drawings and 3D model data for precise manufacturing. Traditional ordering processes are time-consuming and error-prone due to numerous manual and communication-intensive steps needed to communicate exact specifications and obtain quotes.

Even after receiving quotes, manually transferring them into ERP systems or other business software remains a huge challenge. For complex orders, procurement overhead costs for turning and milling parts can amount to as much as 20% of part costs. Manual purchasing processes for CNC parts often result in delays and increased procurement costs.

InstaWerk: Digital Procurement Solution for Turning and Milling Parts

InstaWerk offers an innovative solution for efficient procurement of CNC parts. As a digital manufacturing platform, InstaWerk allows easy online ordering and configuration of custom turning and milling parts.

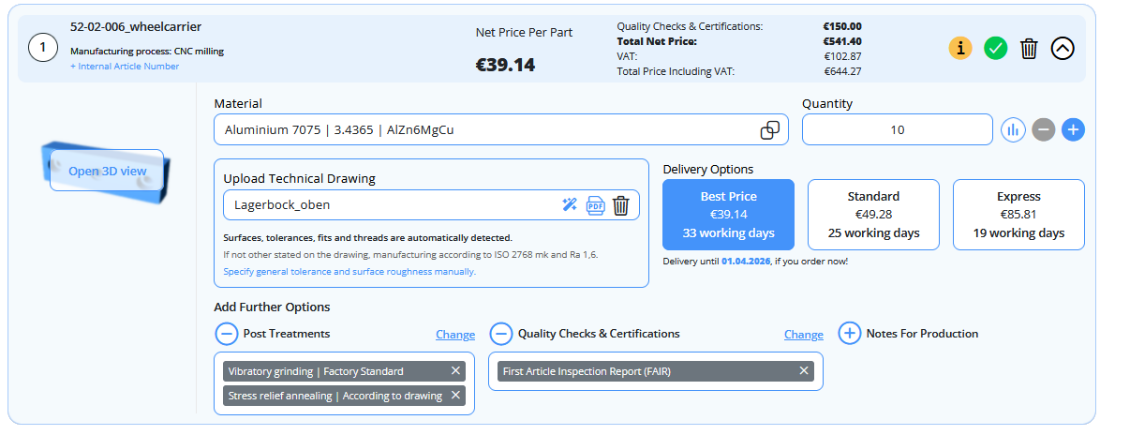

Instant Quoting: Accelerating Order Processes and Enabling Automated Procurement

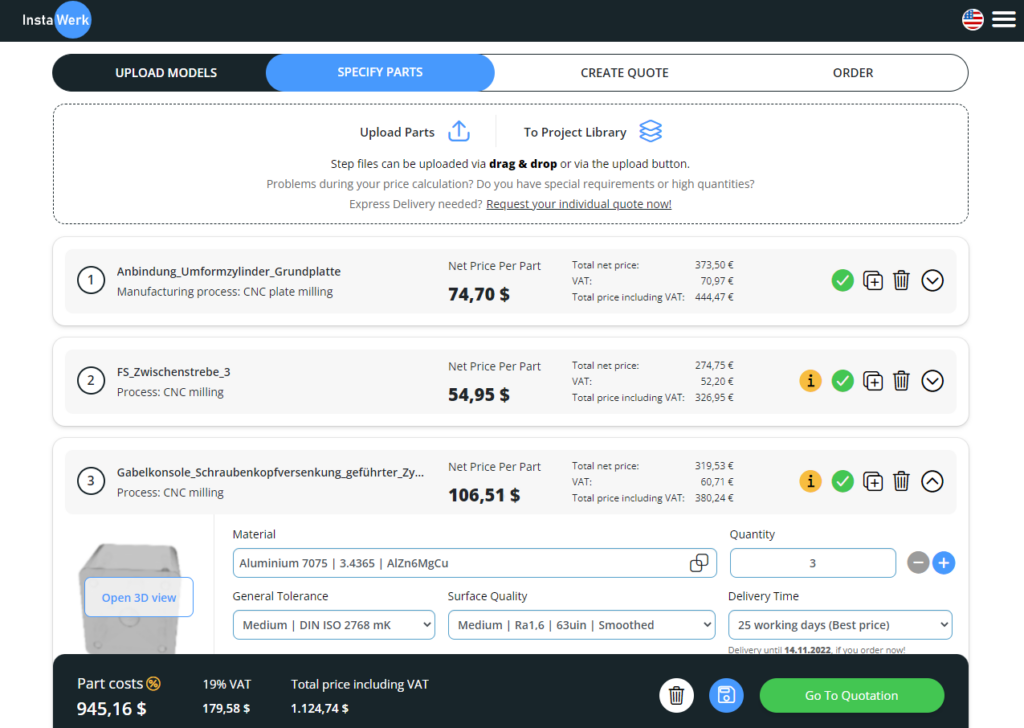

Instant quoting by InstaWerk is a game-changer. Customers can upload their CAD models and drawings directly and receive real-time quotes. This not only speeds up order processes significantly but also integrates seamlessly into automated procurement workflows. Direct integration with ERP systems initiates and processes orders directly from the system, making the entire process more efficient and less error-prone.

Strategic Advantages of InstaWerk for Design, Procurement, and Management

Time Savings: Automating the quoting process allows designers and buyers to receive price quotes for their parts in just a few clicks.

Cost Reduction: Efficient handling of inquiries and orders reduces administrative costs and minimizes expensive errors.

Availability: With access to over 3,000 CNC machines, InstaWerk provides ad-hoc access to virtually unlimited manufacturing capacity.

Integration: InstaWerk integrates smoothly with existing ERP systems, facilitating seamless procurement.

New Feature: OCI Interface at InstaWerk

With the introduction of the Open Catalog Interface (OCI) at InstaWerk, ordering custom machined parts is now even easier and more efficient. For the first time, ordering individual manufacturing parts is as straightforward as ordering catalog items.

What is OCI and How Does Punch-Out Work?

The Open Catalog Interface (OCI) is a standardized interface that integrates external product catalogs into ERP systems. The punch-out process allows direct access from the ERP system to InstaWerk’s quoting system, where products can be configured and then transferred back into the ERP system. InstaWerk supports OCI versions 4.0 and 5.0.

Ordering Process for Turning and Milling Parts via OCI

- Integration: Configure the OCI interface in your ERP system, setting specific parameters detailed in our documentation.

- Punch-Out: Access InstaWerk’s quoting system directly from your ERP system via OCI.

- Configuration: Configure the required turning and milling parts in the catalog and add them to the cart.

- Transfer: Transfer the cart back into your ERP system with one click to complete the order.

Utilizing InstaWerk’s OCI interface offers several strategic advantages. Direct integration with ERP systems minimizes manual steps, significantly enhancing efficiency. Real-time pricing and immediate access to instant quoting accelerate the order process. Additionally, the use of Secure OCI ensures secure data transmission. Finally, the solution is flexible and can be tailored to your company’s needs, enabling cost-effective and swift implementation.

Collaborate with InstaWerk

InstaWerk provides a modern and efficient solution for procuring custom CNC turning and milling parts. By combining Instant Quoting with the new OCI interface, the entire process from inquiry to order is simplified and accelerated. Your company will benefit from increased efficiency, reduced costs, and enhanced digitalization in procurement processes. Start collaborating with InstaWerk today and experience the benefits of digital procurement.