InstaWerk, the German online manufacturing platform for CNC milling has added three new brass alloys and two bronze alloys to its online calculation options. These alloys offer a range of benefits, from high strength to excellent corrosion resistance, making them ideal for a wide range of industrial applications.

- CuZn40Pb2 is a brass alloy that is easy to machine, has good strength, and is highly resistant to wear and tear. Its high lead content makes it less suitable for food and drink applications, but it is commonly used in the automotive, marine, and plumbing industries.

- CuZn39Pb3 is similar to CuZn40Pb2, but it contains less lead, making it a better choice for food and drink applications. This alloy also offers excellent machinability, strength, and wear resistance, making it a popular choice in the automotive and plumbing industries.

- CuZn40 is a brass alloy that offers good corrosion resistance, making it ideal for marine and architectural applications. It also offers excellent machinability and can be used in the production of musical instruments and electrical connectors.

- CuSn8 is a bronze alloy that offers excellent corrosion resistance, making it ideal for marine and oil and gas applications. It is also highly resistant to wear and tear and has good machinability. This alloy is commonly used in the production of gears, bearings, and bushings.

- CuSn12-C is another bronze alloy that is highly resistant to wear and tear and offers good corrosion resistance. It is often used in the production of gears, bushings, and bearings, as well as in marine and oil and gas applications.

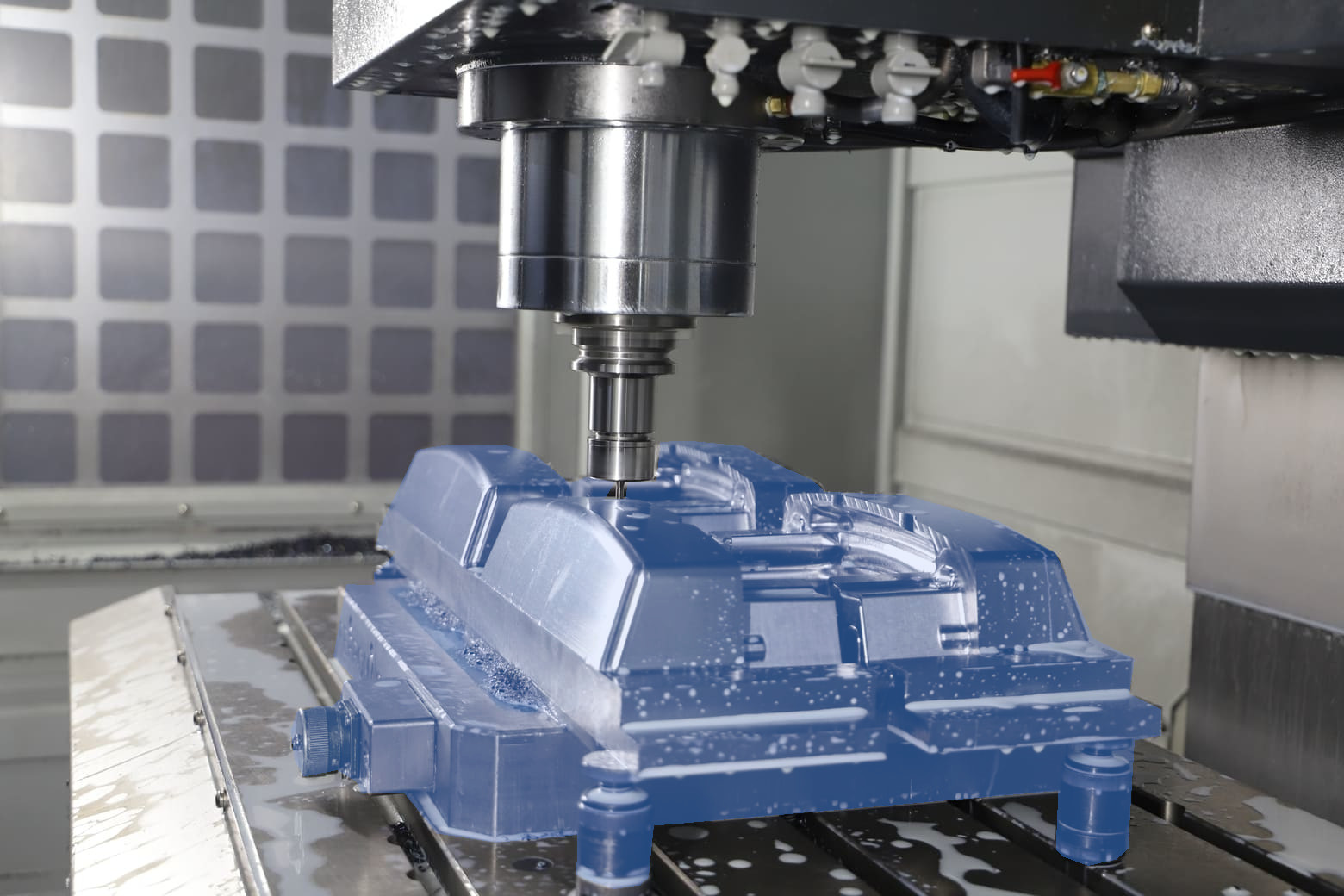

CNC Machining of Copper, Brass and Bronze made easy

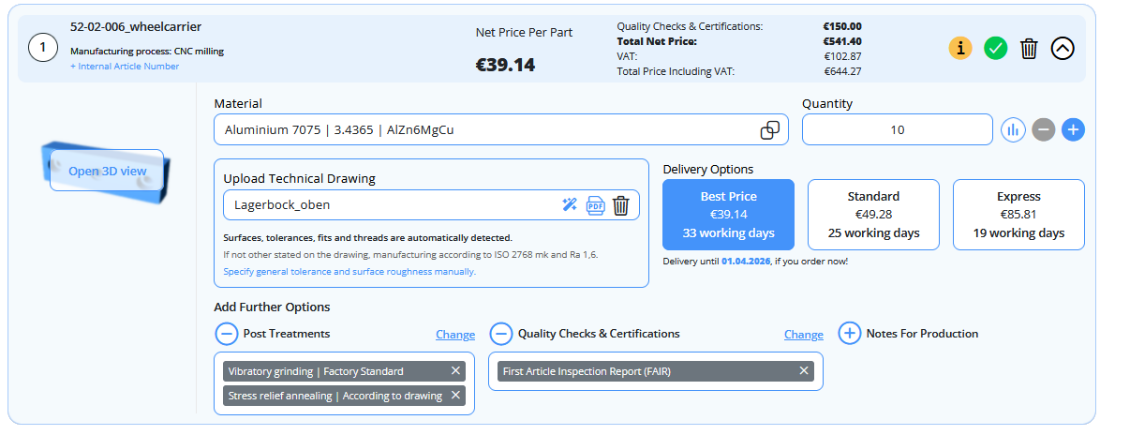

Using the online manufacturing platform for CNC milling allows for cost-effective procurement of brass and bronze parts, while ensuring high-quality standards and a resilient supply solution. Customers can easily calculate and order their parts online, saving time and money in the process. With the addition of these new alloys, the platform offers even more flexibility and options for customers in need of high-quality brass and bronze parts.

In conclusion, the online manufacturing platform for CNC milling offers a wide range of brass and bronze alloys, each with its unique advantages and applications. From automotive to marine and oil and gas industries, these alloys can be used in a variety of applications, and the platform offers a cost-effective and reliable supply solution for all.