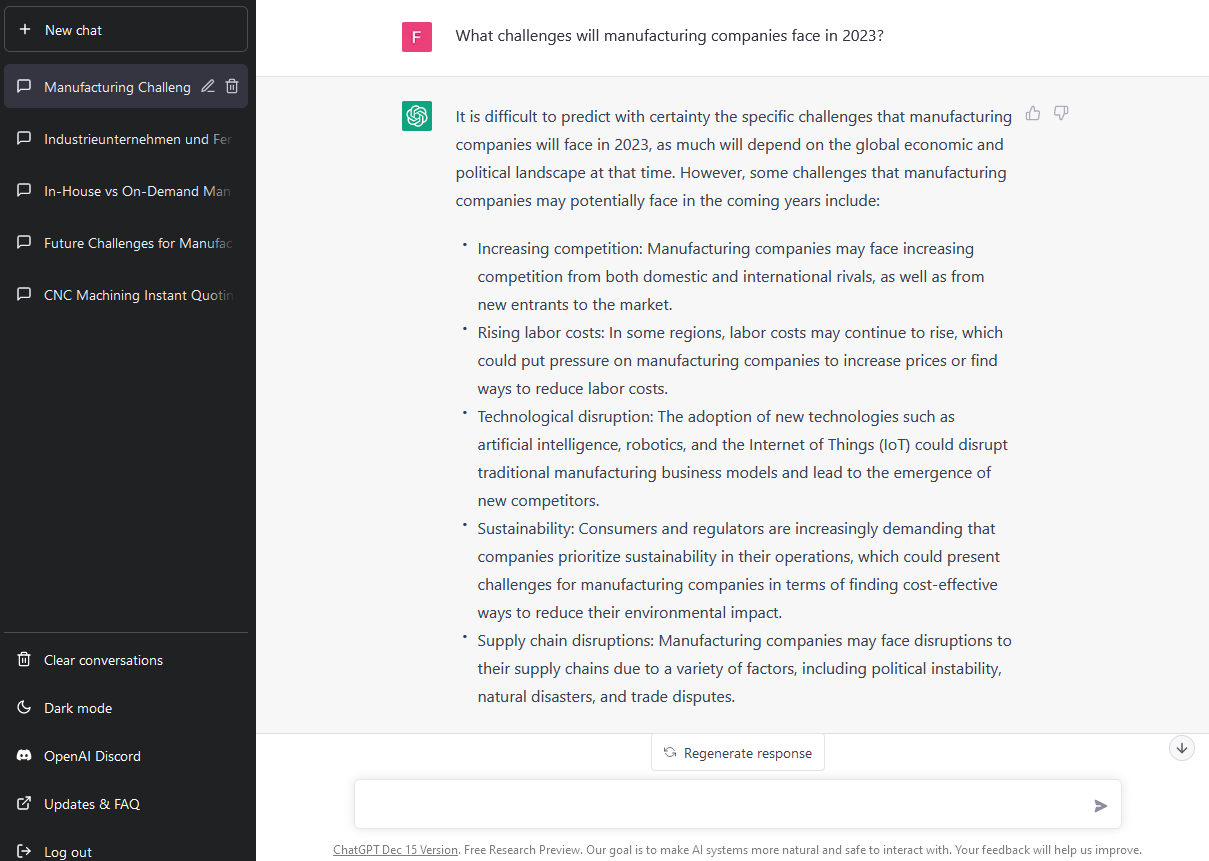

ChatGPT has certainly dominated the headlines in the world of technology in 2022 and will be a hot topic throughout 2023. The artificial intelligence-based system, developed by OpenAI, answers questions automatically using RLHF (Reinforcement Learning from Human Feedback) as well as Proximal Policy Optimization (PPO). For example, we asked ChatGPT how it answers questions and here is the answer we received within seconds:

As an AI language model, I am able to generate human-like text by predicting the next word or words in a sentence based on the input I receive. When answering questions, I use my knowledge and understanding of language and the topic at hand to generate a response that is relevant and informative. I do not have access to the internet and cannot browse or search for information, so my responses are based on the knowledge and information I was trained on during the development process.

ChatGPT

As a Manufacturing Platform, we rely heavily on AI for our automated instant-quoting of CNC parts. So what could be more obvious than asking ChatGPT about the future of manufacturing in 2023? We were interested in how well ChatGPT understands our industry and can predict trends – and indeed we were surprised by the responses. Here are our questions and the answers we received from ChatGPT.

What challenges will manufacturing companies face in 2023?

It is difficult to predict specific challenges that manufacturing companies will face in 2023, as the future is always uncertain and can be affected by a wide range of factors. However, some challenges that manufacturing companies may face in the near future include:

- Technological change: Manufacturing companies may need to adapt to new technologies, such as artificial intelligence, robotics, and the Internet of Things, in order to remain competitive.

- Skilled labor shortages: There may be a shortage of skilled workers in the manufacturing sector, which could make it difficult for companies to find and retain the talent they need.

- Trade policies and tariffs: Changes in trade policies and tariffs could affect the cost and availability of raw materials and finished goods.

- Environmental regulations: Companies may need to adapt to new regulations related to environmental sustainability and emissions.

- Economic uncertainty: Manufacturing companies may face economic uncertainty due to factors such as changes in consumer demand, fluctuations in currency exchange rates, and the impact of global events.

Overall, manufacturing companies will likely need to be agile and adaptable in order to navigate these and other challenges.

Which challenges will buyers of manufacturing goods face in 2023?

It is difficult to predict specific challenges that buyers of manufacturing goods will face in 2023, as the future is always uncertain and can be affected by a wide range of factors. However, some challenges that buyers may face in the near future include:

- Competition: Buyers may face increased competition from other companies for the goods they are seeking to purchase.

- Cost: The cost of manufacturing goods may fluctuate due to factors such as changes in raw material prices, labor costs, and trade policies.

- Quality: Buyers may need to ensure that the goods they are purchasing meet their quality standards.

- Supply chain disruptions: Disruptions in the supply chain, such as shipping delays or shortages of raw materials, may affect the availability and delivery of goods.

- Environmental and social responsibility: Buyers may face pressure to consider the environmental and social impact of the goods they are purchasing.

Overall, buyers of manufacturing goods will likely need to be proactive and strategic in order to navigate these and other challenges.

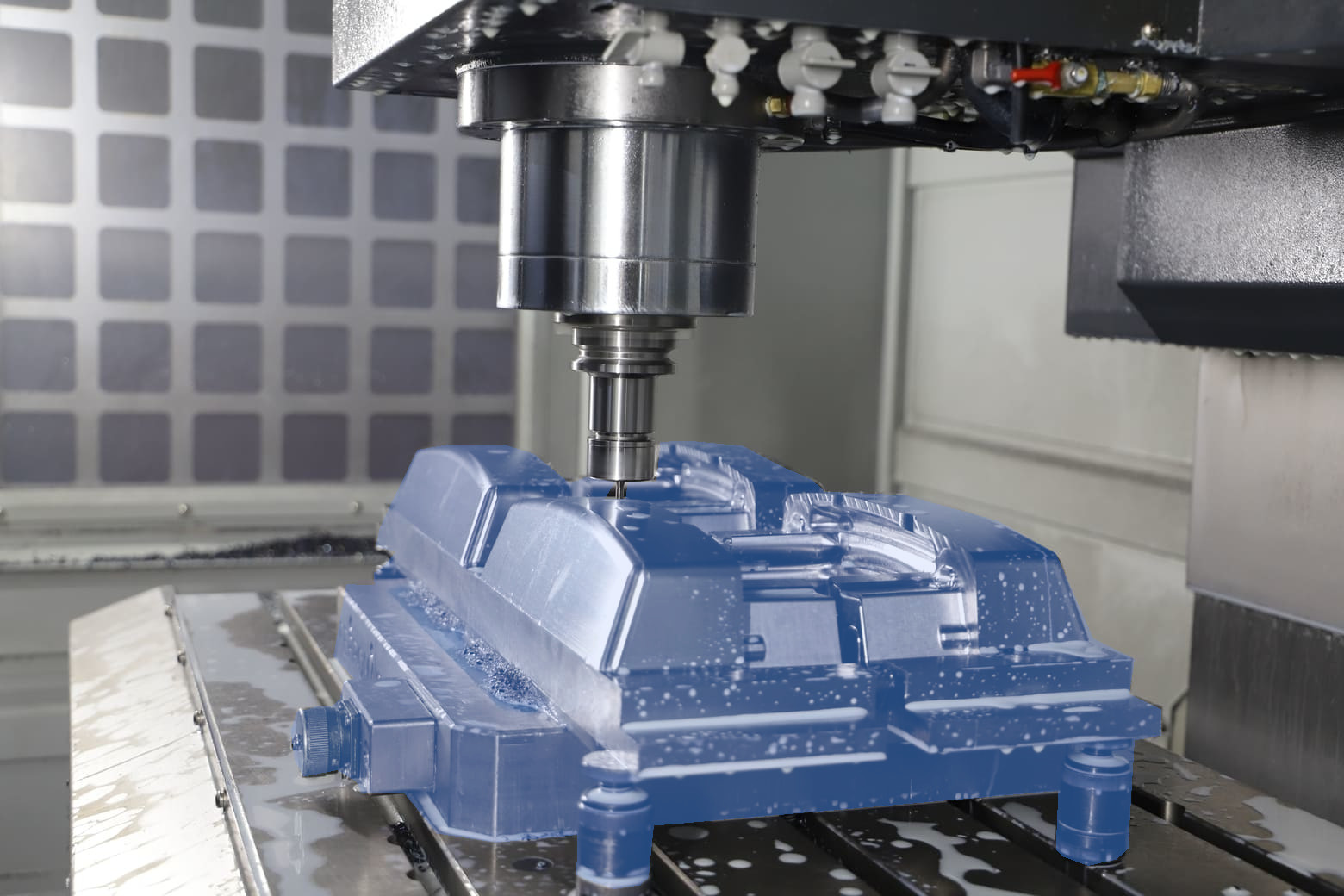

How will manufacturing platforms impact CNC-machining in 2023?

Manufacturing platforms, which are online platforms that connect manufacturers with suppliers and service providers, are expected to have a significant impact on CNC machining in 2023 and beyond. These platforms allow manufacturers to more easily find and compare quotes from different CNC machining service providers, streamlining the sourcing process and potentially saving time and resources.

In addition, manufacturing platforms can provide a wide range of information and resources for manufacturers, including technical specifications, pricing data, and customer reviews, which can be helpful in making informed decisions about CNC machining services.

Manufacturing platforms can also facilitate collaboration and communication between manufacturers and service providers, enabling them to exchange information and ideas more easily and efficiently. This can lead to more efficient and effective CNC machining projects, as well as stronger relationships between manufacturers and service providers.

Overall, manufacturing platforms are likely to play a key role in the CNC machining industry in 2023 and beyond, by providing manufacturers with greater access to information, resources, and collaboration opportunities, and by streamlining the sourcing and procurement process.

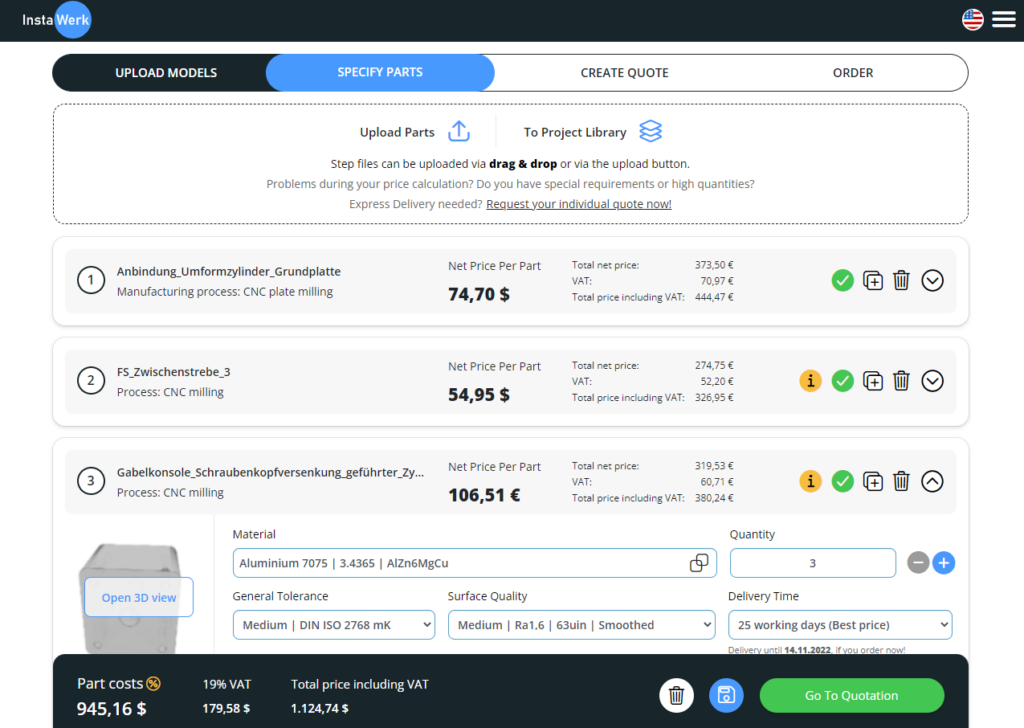

Why will advanced technology companies use manufacturing platforms like Instawerk in 2023?

Advanced technology companies may use manufacturing platforms like Instawerk in 2023 and beyond for a variety of reasons. Some potential benefits of using these platforms include:

- Access to a wide range of suppliers and service providers: Manufacturing platforms can provide advanced technology companies with access to a large pool of CNC machining service providers, which can be helpful in finding the best fit for their specific needs and requirements.

- Streamlined sourcing and procurement process: Manufacturing platforms can help advanced technology companies streamline the process of sourcing and procuring CNC machining services, by providing tools and resources for comparing quotes, negotiating terms, and placing orders.

- Improved collaboration and communication: Manufacturing platforms can facilitate collaboration and communication between advanced technology companies and CNC machining service providers, enabling them to exchange ideas and information more easily and efficiently.

- Access to data and analytics: Some manufacturing platforms may also offer data and analytics tools that can help advanced technology companies track and analyze trends in the CNC machining industry, identify opportunities for improvement, and make more informed decisions about their supply chain.

Overall, manufacturing platforms like Instawerk may be useful for advanced technology companies looking to efficiently and effectively source and procure CNC machining services, as well as improve collaboration and access data and analytics.

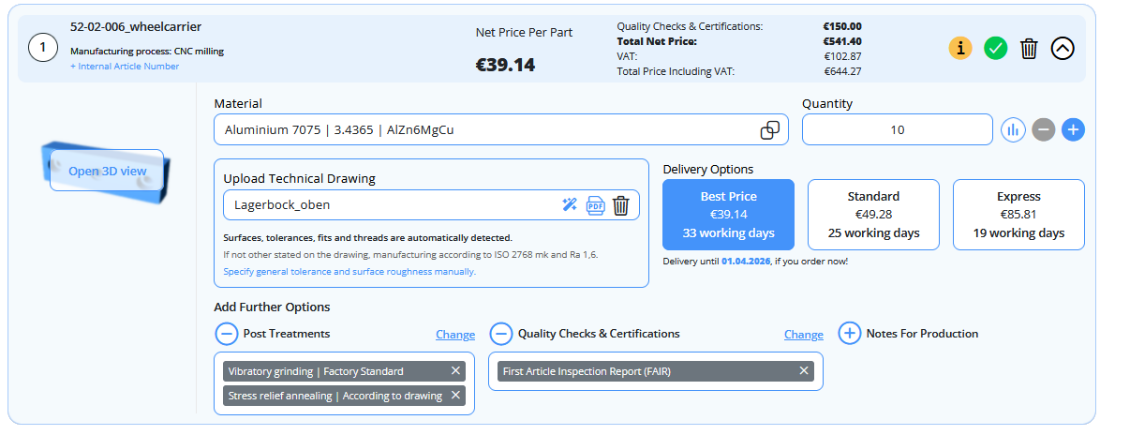

What will instant quoting for CNC machining look like in 2023?

It’s difficult to predict exactly what instant quoting for CNC machining will look like in 2023, as it depends on the development and adoption of various technologies and processes. However, it is likely that there will be a continued trend towards digitization and automation in the manufacturing industry, which may lead to the development of more advanced and efficient methods for generating quotes for CNC machining jobs.

One potential development is the use of artificial intelligence (AI) and machine learning to analyze and evaluate CNC machining projects, allowing for the creation of accurate and reliable quotes in real-time. This could involve the use of algorithms that take into account factors such as material properties, machining tolerances, and production volume to generate a quote.

Another possibility is the use of 3D modeling and simulation tools to visualize and analyze CNC machining projects, which could allow manufacturers to generate more accurate quotes and reduce the need for physical prototypes.

Overall, it is likely that the process of instant quoting for CNC machining will continue to evolve and become more streamlined and efficient in the coming years, potentially making it easier and more convenient for manufacturers to obtain quotes and place orders for CNC machining services.

Does artificial intelligence correctly perceive the world of manufacturing?

To be honest, we were already thrilled with the answers that ChatGPT provided to our questions. Of course, the questions don’t go into much depth for an expert, but the basic subject matter is correctly identified and is in line with the industry-wide perspective. Statements like these have also been described to us by many industry insiders at trade shows and in conversations.

We, too, believe that the transformative power of manufacturing platforms is to the advantage of CNC part buyers and manufacturing operations to meet the challenges of supply chains, efficient purchasing and quality requirements. Instant quoting of CNC parts in particular, as we offer at InstaWerk, brings significant time and cost benefits to our customers.

So, all in all, we were surprised how well ChatGPT as an AI-based solution can interpret and reflect facts in manufacturing. Fortunately, our customers mirror us exactly the same impression of the efficiency and convenience of our procurement solution of CNC components.

ChatGPT is therefore an indicator of the possibilities that artificial intelligence will offer us in the future – and we are only at the beginning of a decades-long development. However, other software-based innovations have also shown us how quickly and comprehensively such innovations can become established.

We therefore believe in the opportunities that artificial intelligence can offer us in supply chain management, but also in reducing delivery times and costs for manufacturing parts. By combining AI in supplier management and instant price generation for CNC manufacturing, we are making it easier for our industrial customers to purchase CNC parts and increase competitiveness. And like ChatGPT, we are just at the beginning of the possibilities. Get started now for free!