01

Speed

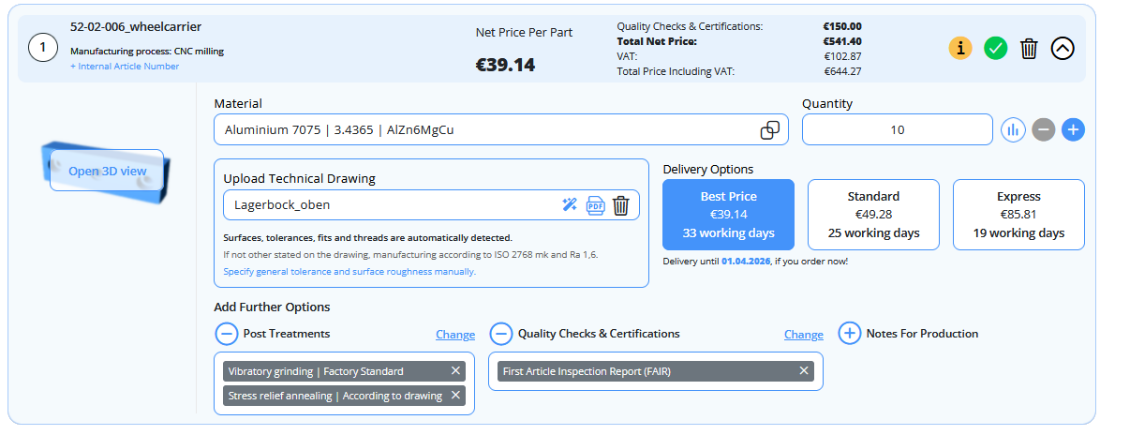

Instant quoting instead of days of back and forth

InstaWerk delivers instant quoting directly from your CAD and drawing inputs – in seconds, not days. Pricing and lead times update in real time as you change quantity, material, tolerances, or finishing. With OCI connectivity and ERP integration, quotes and orders flow into your purchasing process without manual re-entry. That means faster approvals, fewer coordination loops, and a clean audit trail across teams. When time is critical, we can deliver parts from 24h through an expedited production and logistics setup. From first quote to delivered components, Speed is built into every step of the workflow.

02

Ensured Quality

Managed supplier network with continuous in-house performance control

InstaWerk operates under ISO 9001 certified processes to ensure consistent, repeatable delivery quality. Critical dimensions and requirements are validated through our in-house quality hub, including inspection on a Zeiss CMM. Regular supplier audits and performance reviews keep manufacturing standards aligned with your specifications over time. Instead of an open bidding marketplace, we run an exclusive supplier network with defined entry criteria and continuous qualification. Orders are allocated based on capability, quality history, and reliability, not on whoever bids lowest. The result is predictable outcomes, fewer escapes, and stable quality from prototype runs through series supply.

03

Costs

Lower total cost, not just part price

InstaWerk reduces total cost across both part pricing and procurement overhead – with benchmarked savings of around -19.6% on parts and up to -90% on indirect procurement costs. Cost advantages come from automated quoting and ordering, systematic order bundling, and a sourcing setup that combines European and international capacity to match the best cost-performance ratio. Transparent configurations help prevent late-stage changes that typically drive cost spikes. In parallel, structured quality assurance and stable supplier performance reduce the hidden costs of rework, claims, and schedule disruptions. The result is a procurement model that cuts waste across the full cost stack, not just line-item prices.

04

Materials and Finishing

Broad material and post-processing coverage

InstaWerk gives you broad configurability directly in the quoting workflow, with 60+ materials and 40+ post-treatments available across common industrial standards. Beyond standard milling and turning, you can specify advanced operations and special processes to match demanding geometries and requirements. This includes virtually the full spectrum of machining and post-machining steps, such as EDM, precision finishing, deburring, surface treatments, and functional coatings. Options are structured to stay compatible with material-process constraints, so feasibility is built into the configuration. Where requirements go beyond standard catalog options, engineering support ensures the right process chain is defined and executed. The result is a single sourcing path for simple parts and complex, multi-step manufacturing alike.

05

Scalability and Access

From prototype to production volumes without switching vendors

InstaWerk provides access to a manufacturing base of 2,500 machines, giving you high capacity and reliable coverage even when demand spikes. You can source everything from single prototypes to scalable series volumes without switching suppliers or rebuilding processes. Orders are allocated to the best-fit partners based on capability, load, and performance, so scaling does not compromise quality or lead time stability. High availability is designed into the network model, reducing single-supplier dependency and typical bottlenecks. This creates predictable supply continuity for engineering teams and procurement alike. In short, you get industrial-scale capacity with the flexibility of a digital workflow.

06

Availability

Capacity on demand with flexible lead times

InstaWerk gives you immediate access to manufacturing capacity without upfront investment, long-term commitments, or the overhead of building your own supplier base. You can tap into the resources you need exactly when you need them – whether that is a fast prototype loop, an urgent re-order, or additional capacity to stabilize a ramp-up. Lead times and options are configured digitally, while execution is backed by a managed network that can absorb fluctuations. This reduces dependency on single shops and avoids idle internal resources during low-demand phases. The result is on-demand production bandwidth that scales with your workload, not your fixed costs. You stay flexible while still operating with industrial reliability.

07

Digital Continuity

End-to-end digital procurement flow

InstaWerk runs on proprietary, in-house developed software built for end-to-end digital manufacturing procurement. From instant quote and OCI connectivity through to ERP integration, the full process is designed as one continuous workflow, reducing manual handoffs and ensuring clean traceability. The platform is hosted on EU-based infrastructure and operated in a self-hosted setup to maintain full control over the stack. This architecture avoids unnecessary third-party data exposure and minimizes the risk of uncontrolled data flows across vendors. High-performance encryption protects sensitive CAD, drawing and order information throughout the entire lifecycle. The result is a scalable procurement backbone that combines speed, control, and enterprise-grade reliability.

08

Engineering and Commercial Support

Dedicated contact person plus expert review

InstaWerk gives you direct access to an in-house engineering team that supports you with technical feasibility, DFM feedback, and specification alignment. Support is available before, during, and after the order – from early clarification of tolerances and materials to issue resolution and continuous improvement in series supply. Engineers act as a single point of coordination across manufacturing partners, ensuring requirements are interpreted correctly and implemented consistently. In addition to technical guidance, you get commercial support for enterprise procurement needs such as framework agreements, NDAs, and onboarding requirements. This reduces internal coordination effort while improving speed and reliability in decision-making. The result is a procurement experience that feels digital, but never anonymous.

09

Data Security

Closed-network sourcing with controlled data exposure

InstaWerk is built on self-developed, self-hosted software with data storage on European servers, ensuring controlled handling of sensitive CAD and order information. Instead of an open bidding process, projects are assigned to selected suppliers, so your data is not exposed to a broad marketplace or accessible to uncontrolled backend audiences. Access is limited to the partners required to execute the job, following a closed-network sourcing model with defined permissions. To further protect confidentiality, company references can be cleared so drawings and documentation do not reveal the origin of the request where this is required. This approach reduces the risk of unintended disclosure across supply chains and internal stakeholder networks. The result is a procurement workflow designed for enterprise-grade confidentiality

10

Specialization and Experience

CNC turning and milling, executed at scale

InstaWerk supports over 2,500 clients and delivers more than 40,000 parts per month, backed by a highly structured, repeatable execution model. We are specialized in CNC machining, with clear process standards for turned and milled components across a wide range of industrial requirements. This focus enables reliable quoting logic, robust supplier allocation, and consistent quality outcomes at scale. In-house process and material experts ensure that requirements are translated into the right manufacturing route, even for demanding geometries, tolerances, and finishing chains. Lessons learned from high throughput feed directly into continuous improvement across quoting, supplier qualification, and quality control. The result is a partner that combines deep CNC expertise with the operational maturity to perform under real procurement pressure.

Access our unlimited manufacturing ressources now:

Instant Quotes| Unlimited Manufacturing Capacity |

High Quality Exclusive Network | Short delivery times