Focus on high-strength aluminum and stainless steel alloys

Only recently we reported on the expansion of our available materials. At that time, the focus was mainly on plastics and steels. Shortly thereafter, we were also able to offer milled parts made of copper, brass or bronze. Now we have expanded our selection of turned/milled parts by aluminum 2007, aluminum 2017A, aluminum 5754 and stainless steel 316Ti.

In this blog article, we would like to take a closer look at the advantages and disadvantages of each of these materials. In addition, we will explore the benefits to customers of using these materials with Instant Quoting for turned parts and milled parts.

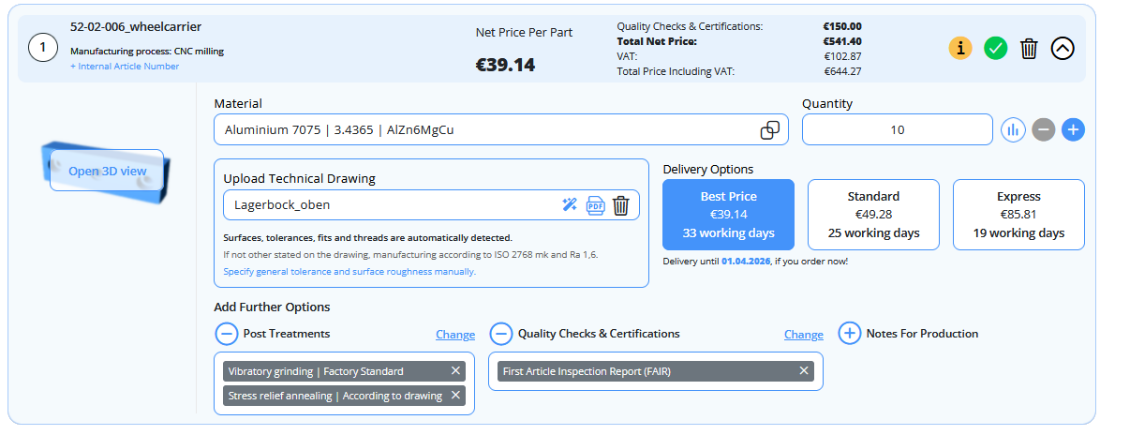

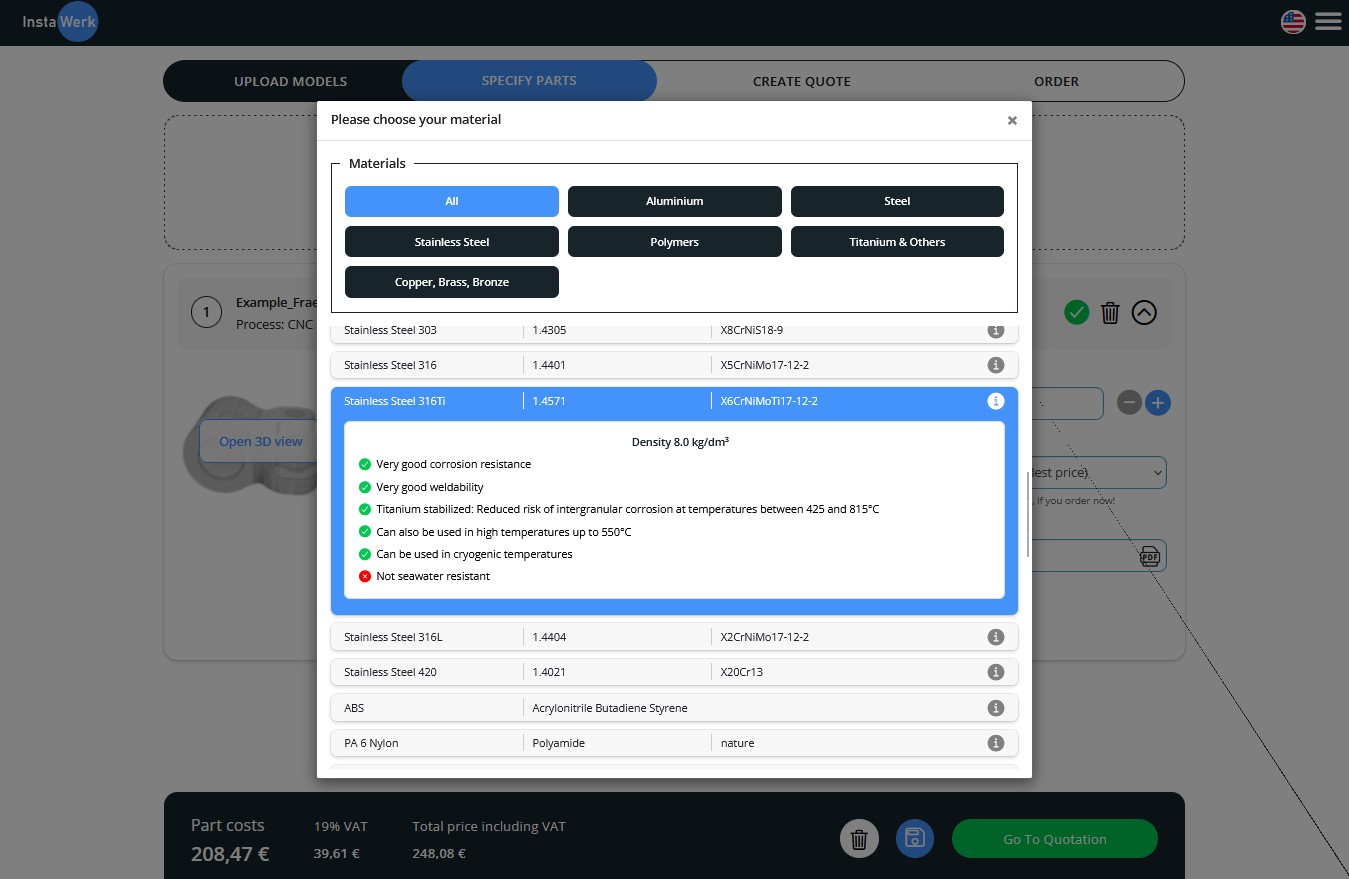

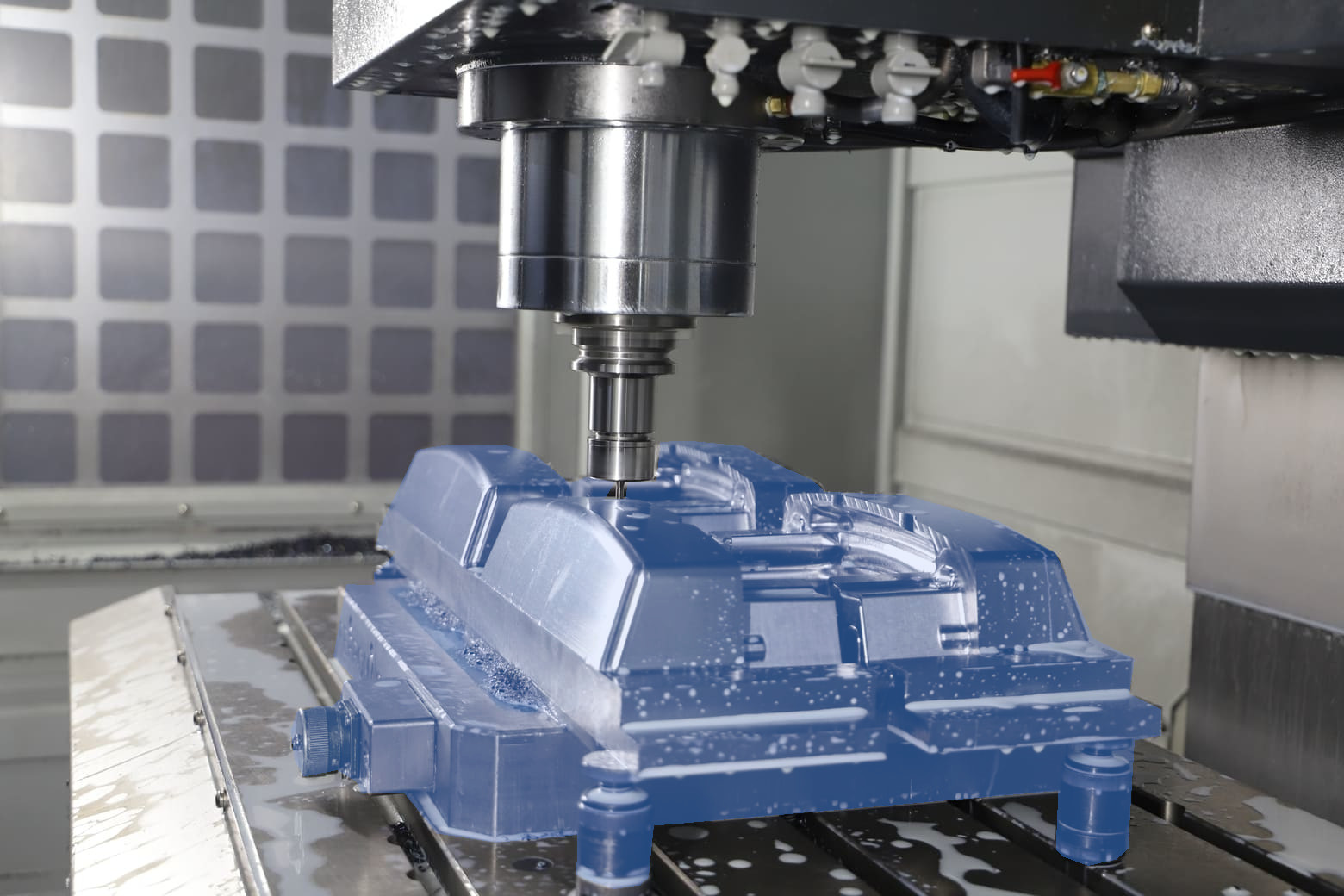

Advanced materials available for instant quoting of turned and milled parts

Aluminum 2007: Aluminum 2007 is a very strong aluminum alloy that has excellent machining properties. It is resistant to corrosion and wear, making it ideal for applications in harsh environments. Due to its high strength and light weight, it is often used for the production of turned parts in the aerospace and automotive industries. However, one of the disadvantages of Aluminum 2007 is that it does not weld very well.

Aluminum 2017A: Aluminum 2017A is another strong aluminum alloy that has good machining properties. It is resistant to corrosion and is well suited for use in harsh environments. Aluminum 2017A is also widely used in the aerospace industry due to its high strength and light weight. One of the disadvantages of aluminum 2017A is that it is prone to cracking and is less suitable for asymmetrical components.

Aluminum 5754: Aluminum 5754 is a medium strength aluminum alloy with excellent corrosion properties. It is excellent for use in marine environments and construction. Aluminum 5754 is also highly weldable, making it suitable for applications that require high weldability. However, one disadvantage of aluminum 5754 is that it is not as strong as other aluminum alloys.

Stainless Steel 316Ti: Stainless steel 316Ti is a heat-resistant stainless steel alloy that resists corrosion and wear. It is well suited for use in harsh environments and for applications that require high resistance to corrosion, such as in the food industry or chemical plants. However, 316Ti stainless steel has a higher cost than other materials and may not be suitable for certain applications.

Curious? Then register for free and try our online calculator for turned and milled parts right away.